Cationic Polyacrylamide Emulsion For wastewater treatment in Oilfield

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 2000Metric Tons per Month

1.Polyacrylamide is used as cationic polyacrylamide in oilfield.

2. Copolymer polyacrylamide in oilfield is used in oily wastewater treatment.

3.Oilfield uses emulsion cationic PAM is running in the pretreatment process.

4. Cationic emulsion for oilfield is more economical(Polyacrylamide price per kg is very low)

Download

Cationic emulsion for oilfield is always running in the dissolve air flotation. There are many kinds of copolymer polyacrylamide in oilfield, which the difference of cationic emulsion for oilfieldare lie in its molecular weight and cationic degree.

Oilfield uses emulsion cationic PAM is running in the pretreatment process,which are always used for oily wastewater treatment.

Using cationic polyacrylamide in oilfield is a emulsion substance made from acrylamide after DMC treatment.

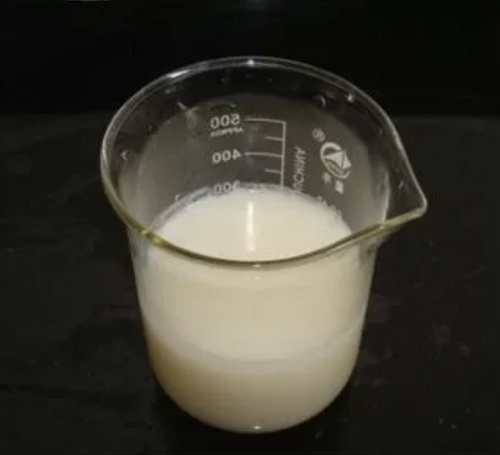

The chemical formula of polyacrylamide anionic is (C3H5NO)n and its appearance is white emulsion. The content of cationic emulsion for oilfield is 45%, the molecular weight is 15~30,the specific granvity is 1.0 and the pH value (1 % aqueous solution) is 6.5~7.5.

Cationic emulsion-type polyacrylamide (CPAM), due to the cationic groups (such as quaternary ammonium groups, amino groups, etc.) on its molecular chain, can efficiently remove pollutants such as suspended solids, colloidal particles, and emulsified oil in oilfield wastewater through charge neutralization and adsorption-bridging effects. Oilfield uses emulsion cationic PAM usage effect is closely related to various conditions. Considering the characteristics of oilfield wastewater, such as high salinity, high oil content, and large temperature fluctuations, the optimal usage conditions can be specifically analyzed from the following aspects:

Preliminary Jar Tests First: The properties of wastewater from different oilfields vary greatly. It is necessary to determine the optimal parameters (ionicity, dosage, pH, etc.) through beaker experiments.

Dynamic Adjustment: If the water quality of the wastewater fluctuates (for example, the mud content increases in the rainy season, or the oil content rises due to changes in the exploitation stage), it is necessary to adjust the dosage in a timely manner or replace copolymer polyacrylamide in oilfield with a matching ionicity.

Equipment Compatibility: The dosing system should avoid high-shear pumps (such as gear pumps) to prevent the breakage of cationic polyacrylamide in oilfield molecular chains. For pipeline materials, plastics (such as PVC) are preferred to avoid the influence of rust from metal pipes on the activity of the chemical. In summary, the optimal usage conditions of cationic emulsion for oilfield wastewater treatment need to be determined comprehensively by combining its own performance, wastewater quality, and operation process. The core is to achieve efficient flocculation through "charge matching + bridging enhancement", and at the same time, reduce treatment costs through synergistic use of chemicals and dynamic adjustment.

Cationic&Anionic PAM products always used for industrial wastewater and sewage treatment.

Industry-specific attributes:

| Name | Polyacrylamide Emulsion | |||

| Chemical Formula | (C3H5NO)n | |||

| CAS NO. | 9003-05-8 | |||

Other Attributes:

| Appearance | Milky,White Viscous Emulsion | |||

| Solid Content | 40% | |||

| Molecular Weight10*6 | 15~30 | |||

| Specific Granvity(25℃) | 1.0 | |||

| Insoluble Substance(%) | 0.1 | |||

| PH Value | 6.5~7.5 | |||

| Dissolving Time,min | <30 | |||

| Cationic charge(%) | 80 | |||

| Storage Temperature,℃ | 0~35 | |||

| Shelf Life,month | 12 | |||

Supply Ability:

| Supply Ability | 2000Metric Tons per Month | |||

Lead Time:

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |