Polyacrylamide for sludge dewatering treatment

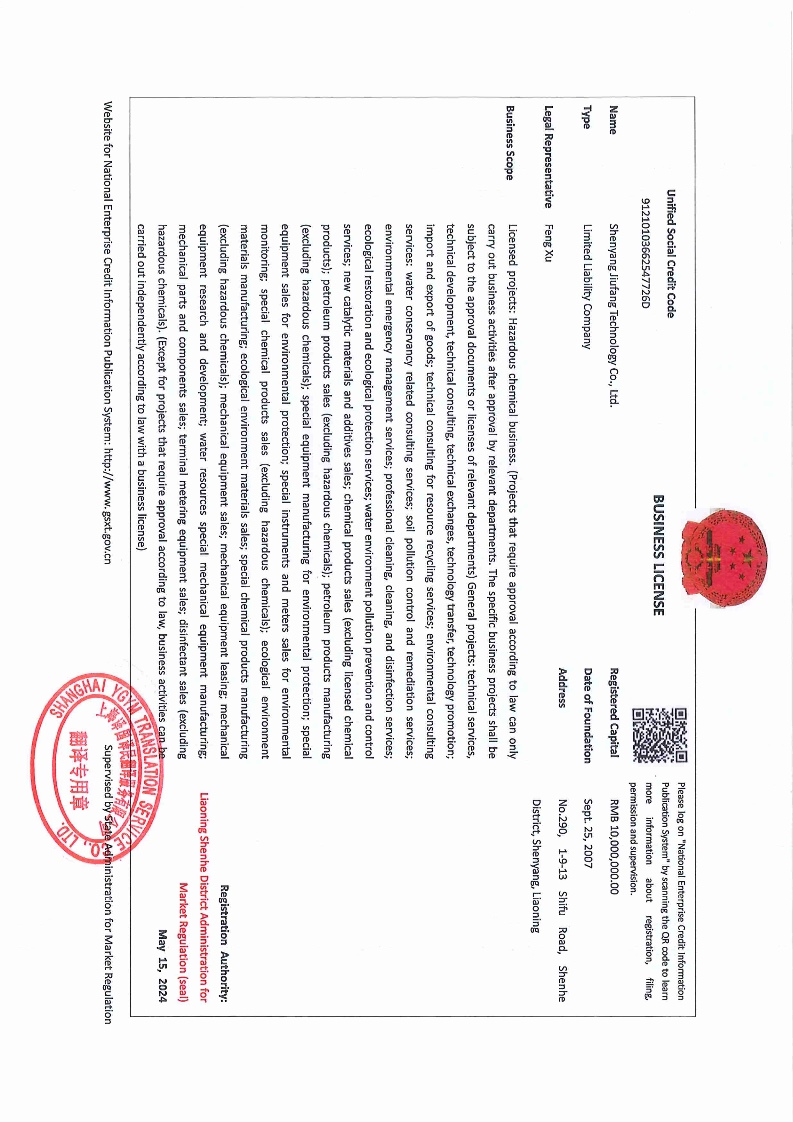

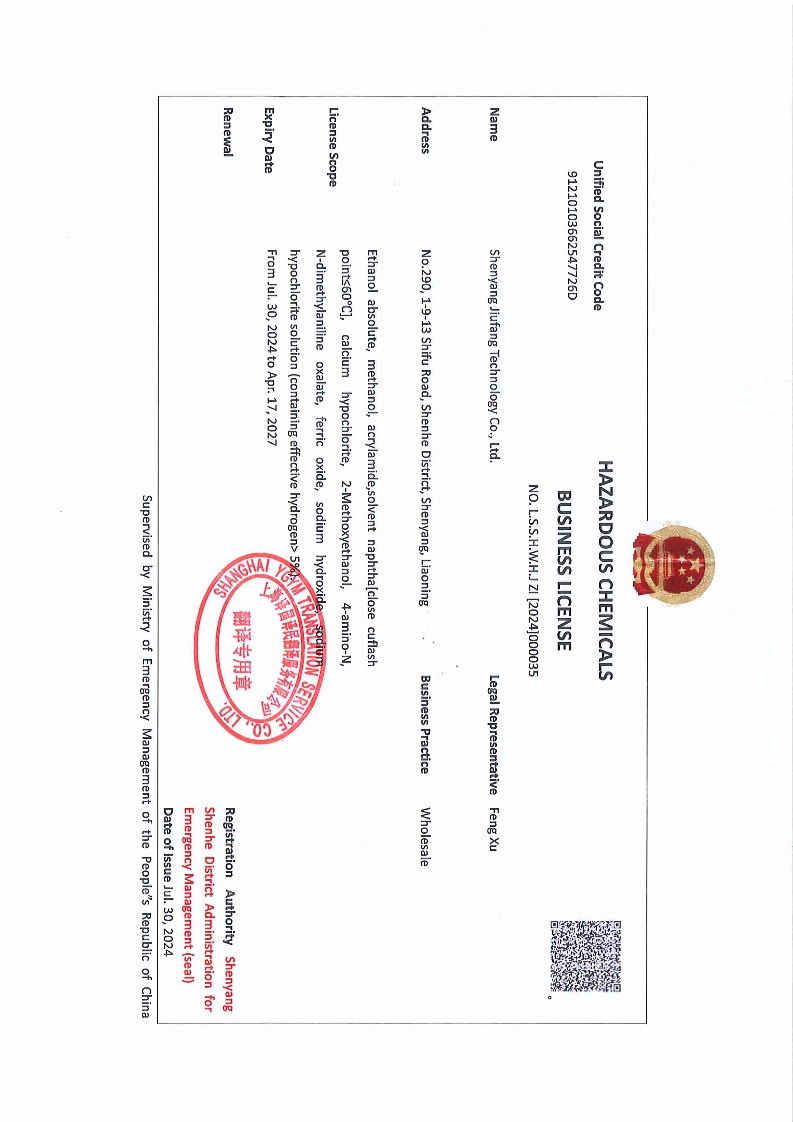

Brand Shenyang Jiufang

Product origin China

Delivery time Lead time: 7days

Supply capacity 10000MT/Year

Cationic PAM is divided into two types of forms: polyacrylamide emulsion & polyacrylamide powder.

Cationic PAM is used for dewatering in the STP, not anionic PAM.

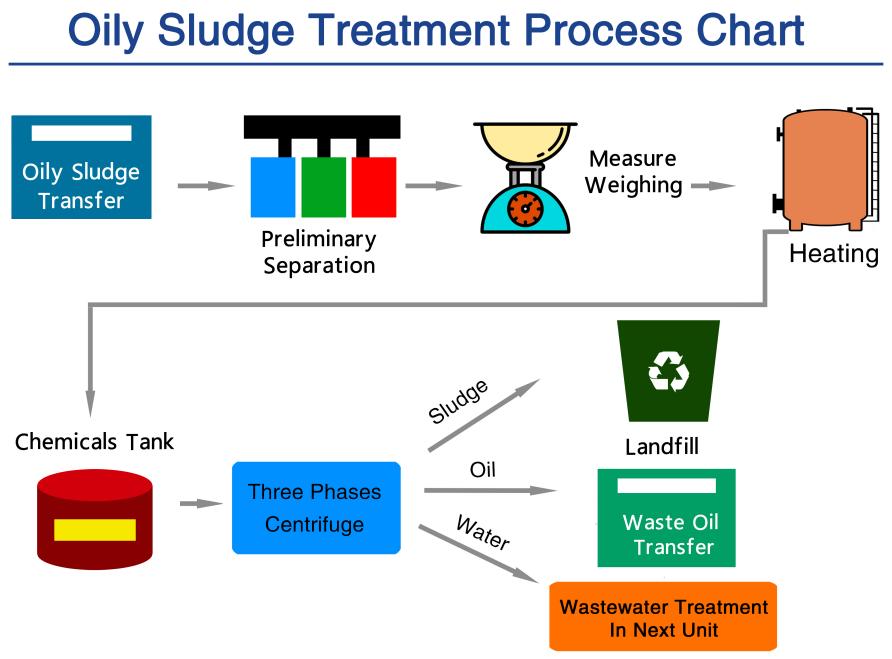

Cationic polyacrylamide for sludge treatment is used in dewatering machines, such as: Centrifuge, belt filter press.

Download

Cationic PAM is a type of polymer with positive charge in its molecular weight. Depending on the on-site situation of dewatering treatment, both polyacrylamide emulsion and polyacrylamide powder can be applied to various dewatering machines.

Polyacrylamide emulsion--There are two types of molecular structures: linear polymer and cross-linked polymer. The cross-linked polymer has better performance than the linear polymer. For instance, it has good filtration performance and good flocs in dewatering. The linear polyacrylamide emulsion is more economical than the cross-linked polymer.

Cationic polyacrylamide for sludge treatment, especially polyacrylamide emulsion, is used for sludge treatment in dewatering. Polyacrylamide powder--This type of polymer is widely used in dewatering after being diluted in special equipment. Copolymer polyacrylamide powder is a polymer that is copolymerized with DAC or DMC. Cationic PAM is not only used in STP but also for oily wastewater treatment in the oilfield.For sludge treatment, especially oily sludge treatment, cationic PAM is suitable for this treatment process.

The core role of cationic polyacrylamide (CPAM) in sludge treatment is to reduce the volume and mass of sludge (especially by reducing the water content to achieve volume reduction). The main function of CPAM focuses on the sludge dewatering stage, improving the dewatering efficiency through flocculation. CPAM is a positively - charged polymer.

It can combine with negatively - charged colloidal particles in the sludge (such as bacteria, organic debris) through charge neutralization and adsorption - bridging, forming larger flocs. By enhancing the dewatering effect, it can reduce the viscosity of the sludge, making it easier for water to separate from solid particles, thus reducing the water content of the sludge (for example, from 95% - 98% to less than 80%), and significantly reducing the sludge volume (when the water content drops from 97% to 80%, the volume can be reduced by approximately 80%).

Cationic polyacrylamide (CPAM) is an important auxiliary agent in the sludge dewatering stage. It can enhance the dewatering efficiency through flocculation and contribute to volume reduction, but it is not the “primary factor” for sludge volume reduction. The core of sludge volume reduction depends on factors throughout the whole process, such as the properties of sludge, the performance of dewatering equipment, pretreatment processes, and stabilization technologies. The function of CPAM can be fully exerted only in combination with these aspects.