Hydraulic Fracturing Friction Reducer

Brand JF

Product origin China

Delivery time Lead time: 7days

Supply capacity 2000Metric Tons per Month

The company boasts strong technical expertise, with senior and mid-level technical personnel accounting for 40% of the total workforce. We prioritize continuous improvement in product quality and performance, while actively engaging in the R&D of hydraulic fracturing friction reducer and innovative products. Particularly adept at targeted R&D and customized hydraulic fracturing friction reducer, we are committed to advancing green technologies to support a low-carbon lifestyle.

Download

Synthesis Theory of New Water-in-Oil Thickener (Drag reducer)Technology:

1. Based on the synthesis theory of water-in-oil emulsion, optimize and improve the synthesis process to enhance product quality.

2. Introduce "salt-resistant monomers" or "temperature-resistant monomers" according to requirements during the synthesis process to improve the temperature and salt resistance of the drag reducer product.

3. Through the green "controlled free-radical polymerization technology", achieve "micro-cross-linked linear polymer emulsion" and multi-branched low-molecular emulsion with controllable molecular weight and molecular structure.

Drag reducer product Characteristics of the New Water-in-Oil Emulsion Thickener:

1. The "controlled free-radical polymerization technology" can achieve controllable molecular weight, reaction rate and molecular structure.

2. The drag reducer has high temperature and salt resistance, and significantly increased viscosity.

3. The drag reducer solves the compatibility problem with cross-linkers and can achieve temperature-induced cross-linking.

4. The product of drag reducer contains less oil phase.

5. It is easy to break the gel, causes low damage, has a low fluid loss and low formation adsorption.

6. It can adapt to a certain degree of complex water quality for liquid preparation and is more economical in dosage compared with traditional water-in-oil emulsions.

1.Suitable for hydraulic fracturing processes in shale oil, shale gas, and coalbed methane.

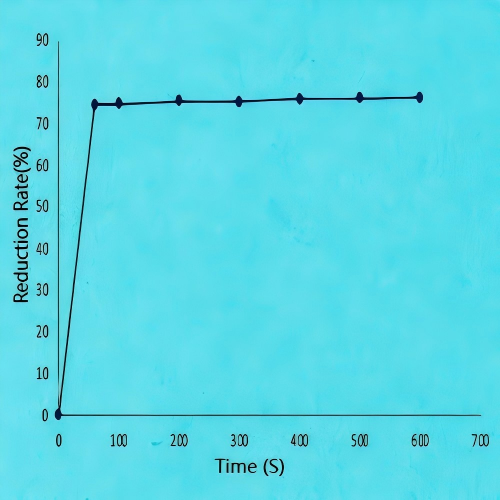

2. High drag reduction rate, meeting the needs of high-displacement operations, with a drag reduction rate >70%.

3. Convenient for construction and easy to prepare.

4. Easily breaks gel, causes low formation damage, and is clean and environmentally friendly.

The drag reducer produced through studying the synthesis mechanisms of water-in-oil and water-in-water emulsion thickeners as well as the synthesis mechanism of salt-resistant powder thickeners can significantly increase the drag reduction rate.

The hydraulic fracturing friction reducer designed through molecular model and synthesized with new salt-resistant and temperature-resistant monomers has a high drag reduction rate.

By optimizing and improving the existing synthesis processes of water-in-oil thickeners and water-in-water thickeners, the salt resistance can be enhanced. The dissolution performance and rapid dispersion performance of powder thickeners can be improved.

Polymer cross-linking at normal temperature or with temperature increase can be achieved to meet complex construction conditions.

Studying the influence of the polymer molecular weight in different distribution ranges or other characteristics on friction resistance, damage, etc. can improve the sand-carrying performance of the hydraukic fracturing friction reducer and increase the migration distance of the proppant.