Cationic fracturing fluid drag reducer

Brand Shenyang Jiufang

Product origin China

Delivery time Lead time: 7days

Supply capacity 10000MT/Year

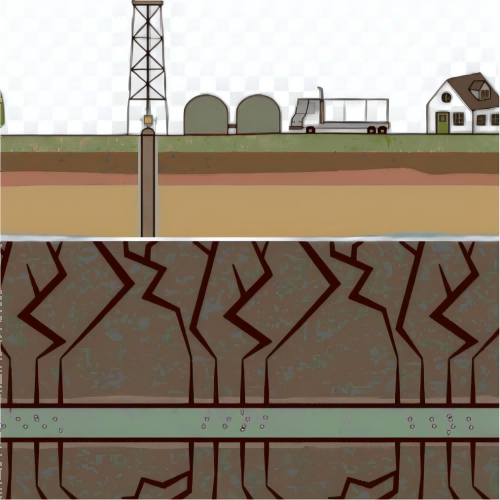

1.The acid thickener(Drag reducer cationic) is a high-molecular emulsified polymer which is a drag reducer(Cationic Acid Thickener) for fracturing fluid.

2. Using drag reducer for fracturing fluids(drag reducing) is a regular product in our company and yearly production is 10000MT/Year.

Download

The applicable conditions of drag reducer cationic need to be comprehensively judged in combination with reservoir characteristics, fracturing fluid systems, construction techniques, and environmental requirements. The core is to adapt to complex scenarios by leveraging the "special functions of cationic groups" and the "stability of drag reducing efficiency".

The specific applicable conditions are as follows:

1. Reservoir Geological Conditions

1). Reservoirs Rich in Clay Minerals

It is applicable to sandstone reservoirs with a clay content> 5%, especially when the reservoir contains expansive clays (montmorillonite, illite - smectite mixed-layer) or easily-migrating fine particles (kaolinite, chlorite).

Reason: Cationic groups can inhibit clay swelling through electrostatic adsorption and anchor dispersed particles, reducing the "water-sensitivity damage" of the fracturing fluid to the reservoir, forming a synergistic protection with the drag reducer function.

2). High-Salinity Formations

It is applicable to reservoirs with a total formation water salinity> 10⁴ mg/L (especially those containing divalent ions such as Ca²⁺ and Mg²⁺), such as inter salt oil and gas reservoirs and coastal - facies sandstone.

Reason: The positively-charged groups of the cationic drag reducer molecular chain are less affected by salt-ion shielding, and can maintain an extended state in a high-salt environment, maintaining the drag reducing efficiency (superior to the "coiling and failure" problem of anionic drag reducer in high - salt conditions).

3). Low-Permeability Reservoirs

It is applicable to tight reservoirs with a matrix permeability < 10 mD, such as shale gas and tight oil reservoirs.

Reason: Low-permeability reservoirs are more sensitive to pore plugging. The dual functions of "anti -swelling + drag reducing" of the cationic drag reducer can reduce the permeability damage caused by the invasion of fracturing fluid filtrate and protect the reservoir's conductivity.

2. Characteristics of Fracturing Fluid Systems

1). Water based Fracturing Fluid Systems

It is only applicable to water based drag reducer for fracturing fluids (including linear gels, cross-linked gels, slickwater, etc.), and is not applicable to oil-based or alcohol-based fracturing fluids.

Reason: The polymer chains of the cationic drag reducer need to dissolve and extend in an aqueous solution to exert the drag reducing effect. The oil-phase environment will cause the molecular chains to coil or precipitate.

2). Complex Systems with Multiple Additives

It is applicable to drag reducer for fracturing fluid systems compounded with cross-linkers (such as borax, organic zirconium), gel-breakers (such as persulfates, enzymes), bactericides, and other additives.

Reason: The cationic drag reducer needs to be compatible with other additives (such as not interfering with gel cross - linking and not being prematurely degraded by the gel - breaker). After molecular design, it can adapt to complex formulations and maintain stability throughout the process. 3.Construction Technique Requirements

1). Long-horizontal-section or Deep-well Fracturing

It is applicable to horizontal wells with a horizontal section length > 1000 m or deep-well fracturing with a vertical depth > 3000 m.

Reason: The frictional resistance along the long horizontal section/deep well is high (the frictional resistance loss can reach 30%-50% of the total pump pressure). The cationic drag reducing can reduce the turbulent frictional resistance by 40%-70%, reducing the pump-pressure loss and ensuring that the fracturing fluid enters each cluster of fractures evenly according to the designed displacement.

2). High-displacement Construction Scenarios

It is applicable to large-scale fracturing (such as volumetric fracturing) with a construction displacement > 10 m³/min.

Reason: At high displacements, the turbulence intensity of the fluid is higher, and the demand for drag reduction is more urgent. The long-chain molecules of the cationic drag reducer can more effectively suppress vortices and maintain a low - frictional - resistance state.

4. Environmental and Stability Requirements

1). Medium to High Temperature Reservoirs (Requiring Temperature - Resistant Modification) Conventional products are applicable to reservoirs ≤ 120℃. After temperature - resistant modification (such as introducing aromatic rings and heterocyclic groups), they can be applicable to high - temperature reservoirs of 120-180℃.

Reason: High temperatures can cause thermo-oxidative degradation of polymer chains. Molecular design is required to improve heat resistance and avoid a decrease in drag reducer for fracturing fluid efficiency due to molecular chain breakage.

2. Low pH or Neutral Fracturing Fluid Environments

It is applicable to use drag reducer for fracturing fluid systems with a pH of 5 -9. A strongly acidic (pH < 3) or strongly alkaline (pH > 11) environment may cause the cationic groups to fail (such as imbalanced protonation of amines).

Summary

The core applicable logic of cationic drag reducer for fracturing fluid drag reducers is: on the basis of "the need for drag reduction", superimposed with scenarios where "the reservoir needs anti-swelling/salt-resistance". Its optimal application scenario is: a high salinity and low permeability reservoir containing expansive clays, using drag reducer for fracturing fluid for long - horizontal - section and high - displacement fracturing construction, and the reservoir temperature is within its temperature - resistant range.