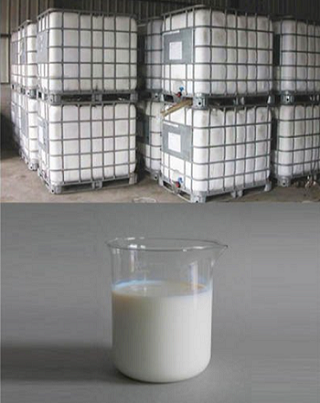

Cationic PAM Emulsion For Sludge

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 2000Metric Tons per Month

1.PAM cationic product could be used for dewatering process in STP.

2. PAM emulsion is easily soluble in water and emulsion polyacrylamide for sludge treatment is a PAM cationic product.

3. Emulsion polyacrylamide for sludge could be used for sewage and wastewater treatment.

Download

In low temperature environments (usually referring to < 15°C, especially < 10°C), the dewatering efficiency of cationic emulsion polyacrylamide (PAM emulsion) significantly decreases due to issues such as reduced reagent activity, deteriorated sludge properties, and slowed reaction kinetics. To improve the low temperature dewatering efficiency, it is necessary to specifically address the core contradictions such as "insufficient reagent dissolution, insufficient molecular chain activity, high sludge viscosity, and lagging flocculation reaction".

The specific measures are as follows:

1. Optimize the Dissolution and Activation of polyacrylamide for sludge: Ensure Sufficient Molecular Chain Extension Low temperature significantly reduces the dissolution rate of polyacrylamide for sludge emulsion, preventing the molecular chains from fully stretching (curled molecular chains are difficult to play a bridging role), which is the primary cause of the efficiency decline. It is necessary to start with the dissolution conditions to enhance the reagent activity.

2. Adjust PAM emulsion Performance Parameters: Match the Characteristics of Low Temperature Sludge Under low temperature conditions, the properties of oily sludge change significantly:

① The viscosity of grease increases (for example, the viscosity of crude oil rises exponentially as the temperature decreases), and the oil film has a stronger wrapping effect on particles;

② The absolute value of the Zeta potential of sludge colloidal particles increases (the negative charge becomes stronger), enhancing the dispersion stability;

③ The mobility of water molecules decreases, making it more difficult to remove the bound water between particles. It is necessary to adjust the key parameters of polyacrylamide for sludge accordingly.

3. Strengthen Pretreatment and Synergistic Effects: Reduce Low Temperature Interference Improving the low temperature characteristics of sludge through pretreatment or synergizing with other reagents can significantly enhance the effectiveness of PAM emulsion.

4. Optimize the Flocculation and Dewatering Processes: Adapt to Low Temperature Reaction Kinetics The flocculation reaction rate slows down at low temperatures (the molecular diffusion rate decreases by more than 50%). It is necessary to adjust the process parameters to extend the reaction time and enhance the stability of the flocs.

5. Ensure the Storage Stability of the Reagent: Avoid Low Temperature Inactivation PAM emulsion is prone to stratification and demulsification due to the failure of the emulsifier at low temperatures (it may freeze below 0°C), resulting in a decrease in activity.

Storage protection measures need to be taken: Control the storage temperature between 5-25°C (achievable through insulated tanks or trace - heating devices).

Shorten the storage time to within 1 month (the stability of the emulsion decreases at low temperatures, and stratification may occur after more than 1 month).

Stir for more than 30 minutes before use to ensure the homogeneity of the emulsion (to avoid uneven concentration caused by stratification).

The core of improving the dewatering efficiency of PAM emulsion at low temperatures is to solve the problems of PAM emulsion dissolution and activity through gentle heating and modified reagents, enhance the charge neutralization and bridging abilities through a high cationic degree and compounding processes, and adapt to the low temperature kinetic characteristics by extending the reaction time and optimizing equipment parameters. The ultimate goal is to form "large, tough, and water-permeable" flocs, creating conditions for water separation. Usually, this can reduce the moisture content of the filter cake at low temperatures by 3%-8%, approaching the treatment level at normal temperature.

Industry-specific attributes:

| Name | Emulsion Polyacrylamide | |||

| Application | Polyacrylamide for sludge treatment | |||

| CAS NO. | 9003-05-8 | |||

Other Attributes:

| Appearance | PAM emulsion | |||

| Activate Content | 48% | |||

| Viscosity Range(ml/g) | 1200~1600 | |||

| Residue | 0.12% | |||

| Insoluble Substance(%) | 0.1 | |||

| Cationic Charge | 80% | |||

| Dissolving Time,min | 40 | |||

| Storage Temperature,℃ | 0~35 | |||

| Shelf Life,month | 12 | |||

Supply Ability:

| Supply Ability | 2000Metric Tons per Month | |||

Lead Time:

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |