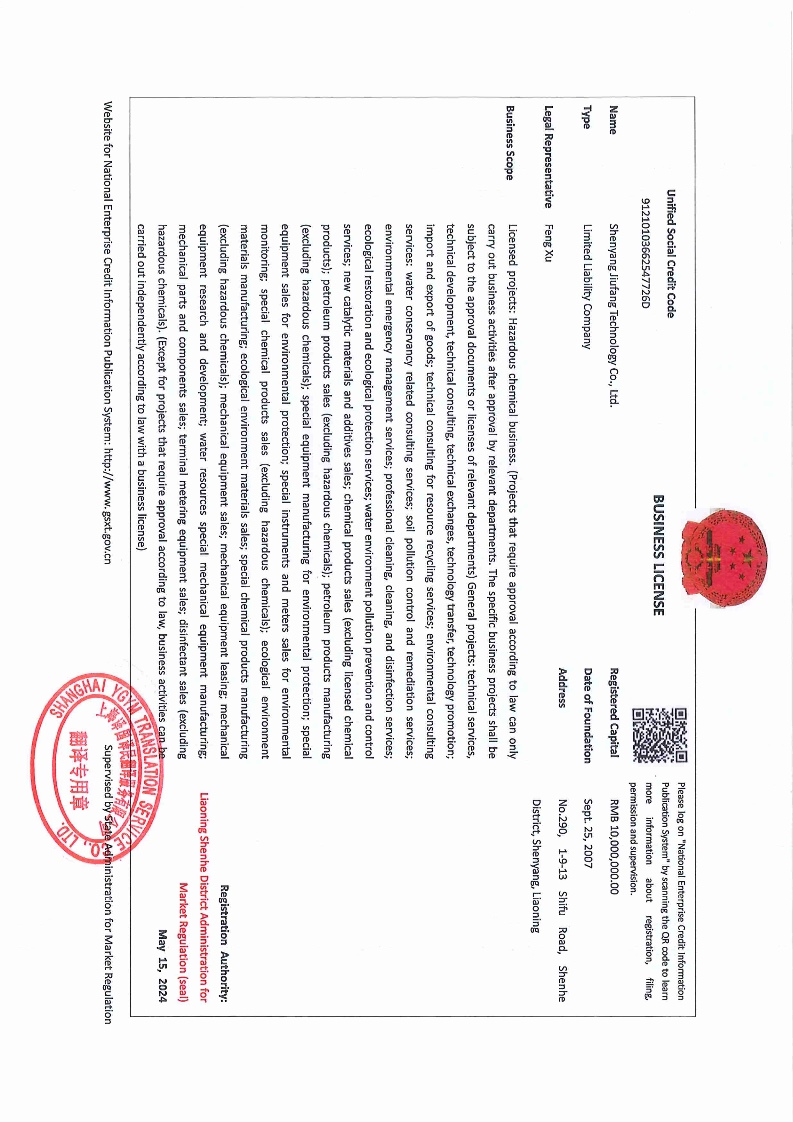

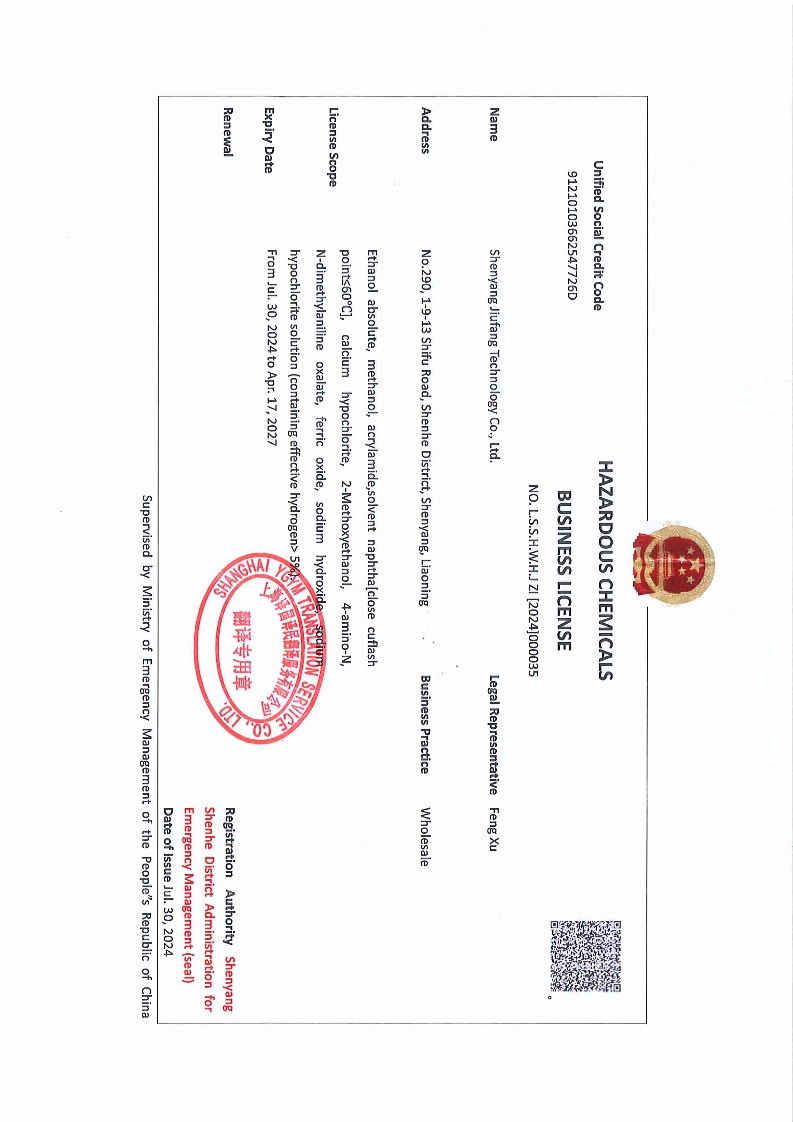

Cationic PAM Emulsion For Wastewater treatment

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 2000Metric Tons per Month

1.Cationic polyacrylamide liquid(our company main product) is a cross-linked polymer product which has a good performance in filtration.

2. CPAM cationic polyeletrolyte emulsion (polyacrylamide)could be used for industrial and domestic water treatment.

Download

There are two forms of polyacrylamide, which is powder and emulsion. PAM for wastewater treatment are used cationic polyacrylamide liquid to treat excess sludge and concentrated high water concent sludge.

The difference of emulsion PAM product wastewater lie in its molecular weight and cationic degree. PAM for wastewater teatment(JF1115) is high degree which is 80% product. And can be easily to treat variety sludge on the site.

Cationic polyacrylamide liquid are always used for produced water treatment and oily sludge treatment in oilfields and refineries.

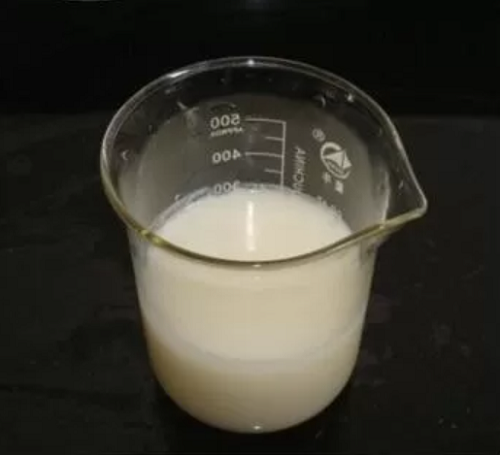

The chemical formula of CPAM cationic polyeletrolyte is (C3H5NO)n and the appearance of PAM for wastewater treatment(emulsion PAM product wastewater ) is white emulsion. The content of CPAM cationic polyeletrolyte emulsion is 48%, the molecular weight is 15~30,the specific granvity is 1.0 and the pH value (1% aqueous solution) is 6.5~7.5.

Steps of Jar Test for Emulsion PAM product wastewater agent(Polyacrylamide)

Step 1: Pretreatment of Sludge Properties

1. Determine basic sludge parameters:

Moisture content: Dry the sludge at 105°C for 2 hours.

pH value: Measure with a pH meter.

MLSS (Mixed Liquor Suspended Solids): Dry at 120°C until constant weight.

Organic matter content: Use the ignition method.

Record the data as the basis for screening (for example, for sludge with a high organic matter content, first test CPAM cationic polyelectrolyte emulsion with an ionic degree of 50% -70%).

Step 2: Flocculation Effect Test (Beaker Stirring Experiment)

1. Pour 1L of sludge into a beaker and place it on a six stirrer. Set the stirring procedure as follows:

Fast stirring: Stir at 300-500 rpm for 1 minute (simulating the pipeline mixing stage).

At the same time, use a pipette to add different doses of CPAM polyacrylamide liquid solution (set 5 gradients according to the dry weight of the sludge, such as 0.1‰, 0.2‰, 0.3‰, 0.4‰, 0.5‰). Add an equal amount of clear water to the blank group.

Slow stirring: Stir at 50-100 rpm for 5 minutes (simulating the flocculation reaction stage to promote the growth of flocs). Stop stirring and let it stand for 3 minutes.

Observe and record:

Floc formation time: Whether it forms within 30 seconds.

Particle size: A particle size of 0.5-2mm is considered excellent.

Compactness: Check if the flocs are loose and easy to break.

Turbidity of the supernatant: Measure with a turbidimeter. A turbidity of ≤10NTU is considered excellent.

Volume of the supernatant: Reflects the sedimentation speed.

Step 3: Dewatering Performance Test (Simulated by Vacuum Filtration)

1. Take 500mL of the flocculated mixed liquid(Polyacrylamide) and pour it into a Büchner funnel lined with filter cloth (the same material as the filter cloth of the actual dewatering machine). Turn on the vacuum pump (negative pressure of 0.06MPa) and record Filtration speed: The volume of the filtrate within 3 minutes (≥200mL is considered excellent).

Filter cake thickness: Measure after 3 minutes (≥1cm indicates high dewatering efficiency).

Moisture content of the filter cake: Weigh the filter cake, dry it at 105°C for 2 hours, and then weigh it again.

Calculate the moisture content using the formula: \((wet weight - dry weight)/wet weight×100\%\).

Peelability of the filter cloth: Observe whether the filter cake adheres to the filter cloth. No adhesion is considered excellent to avoid clogging of the actual equipment.

Step 4: Data Recording and Screening

1. Score the various indicators of different cationic polyacrylamide liquid samples (for example, 30% for floc quality, 30% for filter cake moisture content, 20% for filtration speed, and 20% for supernatant turbidity). Select 1 - 2 models with the highest comprehensive scores and the corresponding optimal dosages.

Industry-specific attributes:

| Name | Cationic polyacrylamide liquid | |||

| Application | PAM for wastewater treatment | |||

| CAS NO. | 9003-05-8 | |||

Other Attributes:

| Appearance | White Emulsion | |||

| Activate Content | 48% | |||

| Viscosity Range(ml/g) | 1200~1600 | |||

| Residue | 0.12% | |||

| Insoluble Substance(%) | 0.1 | |||

| Cationic Charge | 80% | |||

| Dissolving Time,min | 40 | |||

| Storage Temperature,℃ | 0~35 | |||

| Shelf Life,month | 12 | |||

Supply Ability:

| Supply Ability | 2000Metric Tons per Month | |||

Lead Time:

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |