Cationic PAM Emulsion For Water Treatment

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 2000Metric Tons per Month

1. PAM cationic could be used for dewatering process in STP.

2.Cationic polyacrylamide liquid in water treatment could be used for oily sludge treatment.

3.Emulsion PAM could be used for sewage and wastewater treatment.

Download

1. Using polyacrylamide in Centrifugal Dewatering Process

Process Characteristics: It relies on centrifugal force to separate sludge and water. The sludge is spun out under high speed rotation (2000-4000 rpm). PAM cationic(Emulsion PAM) is required to form high strength flocs (to avoid breakage during centrifugation). The core goals are to reduce the moisture content of the filter cake (usually ≤80%) and the solid content in the supernatant.

Special Requirements for Jar Tests using PAM cationic product for water treatment:

Simulating Centrifugal Force Conditions: Use a laboratory centrifuge (rotation speed 3000-5000 rpm, centrifuging for 5-10 minutes) instead of beaker standing. Test the "moisture content of the filter cake" (by drying method) and "supernatant SS" (required to be ≤500 mg/L) under different PAM cationic(polyacrylamide) dosages.

Evaluating Floc Strength after adding polyacrylamide: Gently stir the flocculated sludge with a glass rod and observe whether the flocs are easy to break (high quality flocs should remain intact with only a small amount of fine particles shedding).

Special Requirements for trial field tests using emulsion PAM:

Add the agent of polyacrylamide in the pipeline static mixer before the centrifuge feed port to test the pipeline mixing effect of the agent and the sludge (to avoid local over dosage/under dosage due to uneven mixing).

Monitor the stability of the centrifuge's discharged sludge: Observe whether the filter cake is continuously discharged (without "sludge breakage") and whether the supernatant is clear (without "sludge leakage"), and record the thickness of the filter cake (usually 3-5 cm is appropriate).

2. Using emulsion PAM in Plate and Frame Filter Press Dewatering Process

Process Characteristics: It dewater by high pressure (0.6-1.2 MPa) squeezing. Polyacrylamide is required to form a filter cake with good permeability (to facilitate the discharge of water through the filter cloth). The core goals are a low filter cake moisture content (≤75%) and easy peelability.

Special Requirements for Small Jar Tests after adding emulsion PAM:

Simulating Squeezing Pressure: Test with a jar test filter press device (pressure 0.8 MPa, holding pressure for 30 minutes). Besides the moisture content, focus on testing the "filter cake peelability" (gently lift the filter cake with tweezers and observe whether it falls off completely without residue) and the "filtration time" (record the squeezing time required to reach the target moisture content, required to be ≤2 hours).

Testing Filter cloth Compatibility: Filter with the actual plate and frame filter cloth (such as polypropylene filter cloth) and observe the amount of filter cloth residue (to avoid blockage caused by the adhesion of emulsion PAM to the filter cloth).

Special Requirements for trial field Tests after adding emulsion PAM:

Pay attention to the filter press cycle: Record the total cycle time of "feeding squeezing cake unloading" (target ≤4 hours) and evaluate whether PAM cationic prolongs the cycle (such as slow feeding due to filter cloth blockage).

Regularly check the filter cloth cleaning effect when using emulsion PAM: Clean the filter cloth after each cake unloading and test the water permeability of the cleaned filter cloth (required to recover to over 90% of the initial value).

3. Using polyacrylamide in Belt Filter Press Dewatering Process

Process Characteristics: It is divided into two stages of "gravity dewatering squeezing dewatering". It relies on the "gravity draining" and "roller pressing dewatering" of the flocs on the filter belt.

PAM cationic(Polyacrylamide) is required to form large and tough flocs (to avoid breakage by roller - pressing). The core goals are a filter cake moisture content of ≤80% and no slipping of the filter belt. Special Requirements for Jar Tests:

Simulating the Gravity Dewatering Stage: After adding polyacrylamide liquid in water treatment, let it stand for 30 seconds and observe the filtrate dripping speed (reflecting the gravity draining efficiency) and the clarity of the supernatant (required turbidity ≤100 NTU).

Evaluating Floc Shear Resistance after adding polyacrylamide liquid in water treatment: Simulate roller pressing with a glass rod (gently press the flocs) and observe whether they break (high quality flocs should maintain their shape and only extrude water).

Special Requirements for trial field Tests:

Test the mixing uniformity of the agent(polyacrylamide) and the sludge (the mixing zone of the belt - type machine is short, and the mixing needs to be optimized through a static mixer or a stirring paddle) to avoid filter belt contamination caused by locally unflocculated sludge.

Observe the running state of the filter belt: Check for "filter - cake deviation" and "filter - belt slipping" (excessive dosage may cause the filter cake to be too soft, reducing the friction coefficient). Adjust the dosage until the filter cake can stably adhere to the filter belt.

Industry-specific attributes:

| Name | PAM Cationic(Polyacrylamide) | |||

| Application | Polyacrylamide liquid in water treatment | |||

| CAS NO. | 9003-05-8 | |||

Other Attributes

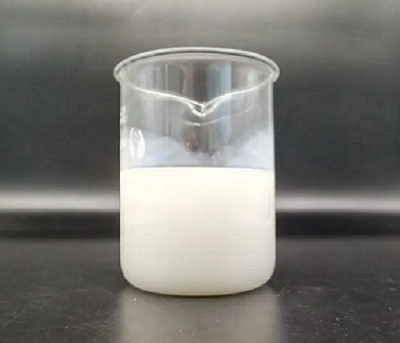

| Appearance | Polyacrylamide white Emulsion | |||

| Activate Content | 45% | |||

| Viscosity Range(ml/g) | 1200~1600 | |||

| Residue | 0.12% | |||

| Insoluble Substance(%) | 0.1 | |||

| Cationic Charge | 80% | |||

| Dissolving Time,min | 40 | |||

| Storage Temperature,℃ | 0~35 | |||

| Shelf Life,month | 12 | |||

Supply Ability:

| Supply Ability | 2000Metric Tons per Month | |||

Lead Time:

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |