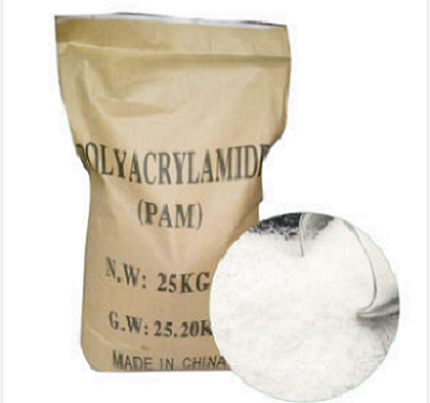

Cationic PAM Powder For oily wastewater treatment in Oilfield

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 2000Metric Tons per Month

1. Cationic powder PAM (polyacrylamide) can be used for the pretreatment of oily wastewater in DAF.

2. Cationic polyacrylamide is suitable for using powder PAM for oily wastewater treatment in oilfield.

3. Cationic polyacrylamide in oilfield is widely used as medium cationic charge PAM.

Download

In the treatment of oily wastewater in oilfields, the selection between branched cationic powder PAM and linear cationic polyacrylamide (CPAM) needs to be comprehensively judged from multiple dimensions, including wastewater characteristics, treatment processes, treatment objectives, and economic efficiency.

The core is to balance "water quality-process-effect-cost".

The following are the specific judgment ideas and steps:

Step1: Analyze the Core Characteristics of Oily Wastewater in Oilfields

This is the primary prerequisite for selecting PAM for oily wastewater treatment in oilfield, and the following indicators need to be detected.

Oil Content and Degree of Emulsification

If the oil content in the wastewater is high (>500 mg/L) and the proportion of emulsified oil is large (oil droplet size <10 μm, such as W/O emulsion, which is difficult to separate into layers after standing), branched cationic powder PAM is preferred. The branched structure of cationic powder PAM can penetrate the emulsion film, strengthen demulsification and oil droplet coalescence, and the oil removal rate is 5%-15% higher than that of linear cationic powder PAM. If the oil content is low (<300 mg/L) and it is mainly free oil (oil droplet size >50 μm, which is easy to float), linear cationic powder PAM can meet the requirements through charge neutralization and long chain bridging, with a lower cost.

2. Salinity (Salt Content)

In high salinity wastewater (total dissolved solids >30000 mg/L, such as containing a large amount of Ca²⁺, Mg²⁺, Cl⁻), linear cationic powder PAM is prone to the shielding of charges by salt ions, causing the molecular chain to curl up, and the flocculation activity decreases by more than 30%. Branched cationic powder PAM must be selected. The steric hindrance of its branches can resist the compression of salt ions, maintaining the stretching and activity of the molecular chain.

In low salinity wastewater (<10000 mg/L), the charge neutralizing ability of linear cationic powder PAM can function normally. If the treatment requirements are not high (such as only removing suspended solids), the linear cationic powder PAM can be preferentially considered to reduce costs.

3. Content and Nature of Suspended Solids (SS)

If the SS content is high (>1000 mg/L) and it is mainly composed of fine particles (<5 μm, such as clay, colloid), the multi point adsorption ability of branched cationic powder PAM can quickly form dense flocs, and the sedimentation speed is 20%-40% faster than that of linear cationic powder PAM, reducing the residence time in the treatment unit.

If the SS is mainly composed of coarse particles (>50 μm), the long chain bridging effect of linear cationic polyacrylamide in oilfield can achieve particle coalescence, without relying on the efficient adsorption of the branched type.

Step 2: Match the Requirements of the Treatment Process

Different treatment units (such as coagulation sedimentation, air flotation, sludge dewatering) have different requirements for the floc characteristics of flocculants, and targeted selection is needed:

1). Coagulation Sedimentation/Clarification Process

If the process requires rapid sedimentation (such as a high load sedimentation tank with a residence time <30 min), the dense and high strength flocs (resistant to water flow shear) formed by branched cationic polyacrylamide in oilfield are more suitable, which can reduce floc breakage.

If there is sufficient residence time (>60 min), the loose flocs of linear cationic polyacrylamide in oilfield can sediment slowly, and with a lower cost, it can be an alternative.

2). Air Flotation Process

Air-flotation requires effective combination of flocs and bubbles ("bubble-floc" adhesion). The porous floc structure of branched cationic polyacrylamide in oilfield is more likely to capture bubbles, with a fast floating speed and higher efficiency in removing oil and SS. The loose flocs of linear cationic polyacrylamide in oilfield may break due to bubble penetration, resulting in poor effects.

3). Sludge Dewatering Process

If subsequent plate frame filtration, centrifugal dewatering, etc. are used, the sludge specific resistance needs to be reduced (to increase the filtration speed). The sludge flocs treated by branched cationic polyacrylamide in oilfield PAM is compact, and the moisture content after dewatering can be reduced by 5%-10%, significantly reducing the sludge disposal cost, so it should be preferentially selected.

If only natural drying is used (with low requirements for moisture content), the cost advantage of linear cationic polyacrylamide in oilfield can be preferentially considered.

Step3: Define Treatment Objectives and Water Quality Standards

If the effluent needs to meet the discharge standard (requiring an oil content <10 mg/L) or be reused (such as reinjected into the formation, with an oil content <5 mg/L), the high-efficiency oil-removal and turbidity reduction ability of branched PAM oily wastewater treatment in oilfield can more easily meet the strict standards and avoid secondary treatment.

If it is only for preliminary pretreatment (such as reducing the oil content to less than 300 mg/L and then entering the biochemical treatment), linear PAM for oily wastewater treatment in oilfield can meet the basic requirements with a lower cost.

Step 4: Economic and Operational Verification

1). Cost Comparison. Due to its complex synthesis process (such as introducing branched monomers and regulating the degree of branching), the unit price of branched PAM for oily wastewater treatment in oilfield is usually 20%-50% higher than that of linear PAM for oily wastewater treatment in oilfield. However, its dosage is 10%-30% lower, and the sludge disposal cost is also lower. It is necessary to calculate the "unit water volume treatment cost" (reagent cost + sludge disposal cost) instead of simply comparing the unit prices. For example, in the treatment of high salt and high oil wastewater, the low dosage of branched PAM for oily wastewater treatment in oilfield can offset the price difference, and the total cost is actually lower. Linear PAM for oily wastewater treatment in oilfield may only have a better unit cost in the case of low concentration and simple water quality.

2). Operational Verification

The branched structure of branched PAM cationic product for water treatment may affect the dissolution speed (requiring a longer stirring time or a higher concentration dissolution), and it is necessary to verify whether the on site dissolution equipment is compatible. Linear PAM cationic product for water treatment is easier to dissolve and is suitable for sites with a low degree of automation.

1. If the wastewater is high salt (>30000 mg/L), high emulsified oil (>500 mg/L), high fine SS,

and the treatment target is strict (such as reuse) → branched CPAM**;

2. If the wastewater is low salt (<10000 mg/L), low free oil (<300 mg/L), coarse SS, and only pretreatment is required → linear CPAM;

3. In between → It is preferred to compare through experiments and select the type with "lower unit treatment cost + more stable effect".

Ultimately, branched PAM cationic product for water treatment is more suitable for complex and stringent oily wastewater treatment in oilfields, while linear PAM cationic product for water treatment is suitable for simple and low cost demand scenarios. Experimental data is the final basis for decision making.

Industry-specific attributes:

| Name | Cationic powder PAM | |||

| Application | PAM cationic product for water treatment | |||

| CAS NO. | 9003-05-8 | |||

Other Attributes:

| Appearance | White Powder | |||

| Solid Content | 90% | |||

| Molecular Weight 10*6 | 8~9 | |||

| Density(25℃) | 0.75g/cm3 | |||

| PH Value(1% water solution) | 6~8 | |||

| Cationic Charge | 70% | |||

| Dissolving Time,min | <30 | |||

| Storage Temperature,℃ | 0~35 | |||

| Shelf Life,month | 24 | |||

Supply Ability:

| Supply Ability | 2000Metric Tons per Month | |||

Lead Time:

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |