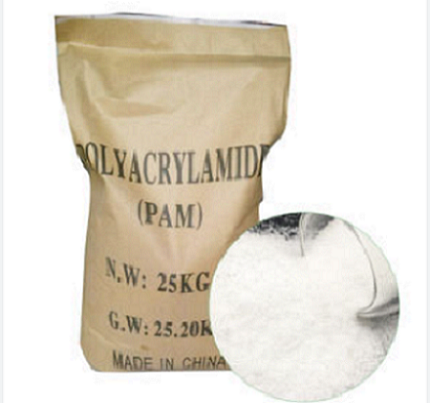

Cationic PAM Powder For Sludge treatment

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 2000Metric Tons per Month

1. Cationic polymer PAM for sludge treatment could be used in variety dewatering machine.

2. Cationic polyacrylamide for sludge treatment could be meet variety treatment process.

3. PAM powder sludge is a abbreviation about using PAM powder to treat the sludge.

Download

1. Classification by degree of cationic polymer PAM for sludge treatment : Core Differences in Charge Neutralizing Ability The cationic degree (the proportion of cationic groups in the cationic polyelectrolyte emulsion CPAM molecule, usually 10% - 80%) is the key to determining the charge neutralizing ability. The capture differences of cationic polymer PAM for sludge treatment emulsions with different cationic degrees are significant:

Low Cationic Degree of cationic polyacrylamide for sludge treatment (10% - 30%):

With few cationic groups, the charge neutralizing ability is weak. It can only neutralize the sludge particles with a low surface negative charge density (such as some inorganic sludges and highly aged activated sludges with weak negative charges).

Medium Cationic Degree of cationic polyelectrolyte emulsion CPAM (30% - 60%):

There is a balance between charge neutralizing and bridging abilities. It is suitable for most sludges with a medium negative charge density (such as municipal mixed sludges and food - industry sludges).

High Cationic Degree ofcationic powder sludge agent (60% - 80%):

With a dense distribution of cationic groups, the charge - neutralizing ability is strong, making it suitable for highly negatively - charged sludges (such as fresh activated sludges with a large number of microorganisms, papermaking sludges, and chemical - industry sludges with a high surface negative - charge density).

2. Classification by Molecular Weight: Core Differences in Bridging Ability

The molecular weight (usually ranging from several hundred thousand to over 20 million) determines the length of the molecular chain, directly affecting the bridging range and the size of the flocs:

Low Molecular Weight (< 5 million): With a short molecular chain, the bridging range is small. It can only connect a small number of adjacent particles, forming flocs with a small particle size (tens of microns) and a compact structure (because the short chain is not easy to stretch).

Medium Molecular Weight (5 million - 15 million): The molecular chain length of cationic powder sludge agent is moderate, with a balance between bridging ability and charge neutralization. It can connect a moderate number of particles, forming flocs with a medium particle size (100 - 300 microns) and a well - structured looseness (balancing strength and water permeability).

High Molecular Weight (> 15 million): With a long molecular chain, the bridging range is wide. It can connect particles across multiple layers, forming flocs with a large particle size (more than 300 microns) and a loose structure (the long chain is easy to entangle).

3. Classification by Molecular Structure: Differences in Bridging Modes and Floc Strength The molecular structure of cationic polyeletrolyte emulsion CPAM is divided into linear and branched (or star - shaped), and the differences are mainly reflected in the group distribution and chain rigidity:

Linear Structure: The molecular chain is linear, and the cationic groups are evenly distributed along the main chain. The chain has good flexibility and is easy to stretch and extend.

Branched (Star - shaped) Structure: Multiple branches extend from the main chain, and the cationic groups are concentrated at the ends of the branches. The chain has slightly higher rigidity and is not easy to over - entangle.

4. Classification by Emulsion Type: Differences in Dispersibility and Reaction Efficiency cationic polymer PAM for sludge treatment emulsions are divided into water - in - oil (W/O) and water - in - water (W/W) emulsions according to the dispersion medium.

The core differences lie in dispersibility and environmental compatibility:

Water - in - Oil Emulsion: With the oil phase as the continuous phase, cationic powder sludge agents molecules are dispersed in water - phase micro - droplets (water - in - oil structure). An emulsifier is required for stabilization, and it usually contains a small amount of oil.

Water - in - Water Emulsion: With water as the continuous phase, cationic polyelectrolyte emulsion CPAM molecules are dispersed in water (water - in - water structure) and contain no oil, which is more environmentally friendly.

5. Classification by Functional Modification: Differences in Adaptability to Special Sludges Some CPAM emulsions are modified by introducing hydrophobic groups, amphoteric groups, etc., to optimize for special sludges:

Hydrophobically Modified CPAM Emulsion: A small number of hydrophobic groups (such as alkyl groups) are introduced into the molecular chain, enhancing the hydrophobic interaction with oily - sludge particles.

The flocs are more compact, and the oil is less likely to block the filter cloth during dewatering. - Amphoteric CPAM Emulsion (Cationic + a Small Amount of Anionic/Non ionic Groups): It has both cationic neutralization and the adaptability of anionic/non ionic groups, making it suitable for complex sludges (such as industrial mixed sludges with large composition fluctuations).

Industry-specific attributes

| Name | Cationic polyelectrolyte emulsion CPAM | |||

| Application | Cationic polymer PAM for sludge treatment | |||

| CAS NO. | 9003/5/8 | |||

Other Attributes

| Appearance | White Powder | |||

| Solid Content | 90% | |||

| Molecular Weight 10*6 | 8~9 | |||

| Density(25℃) | 0.75g/cm3 | |||

| PH Value(1% water solution) | 6~8 | |||

| Cationic Charge | 70% | |||

| Dissolving Time,min | <30 | |||

| Storage Temperature,℃ | 0~35 | |||

| Shelf Life,month | 24 | |||

Supply Ability

| Supply Ability | 2000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |