Cationic Polyacrylamide Emulsion For Wastewater Treatment

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 2000Metric Tons per Month

1.Copolymerization polyacrylamide emulsion is an emulsion polymer polymerized under a special process..

2.Polyacrylamide polymer emulsion could be used for oily sludge treatment.

3.Polyacrylamide PAM in wastewater uses is used in dewatering process of sewage and wastewater treatment.

Download

The core logic of choosing the molecular weight of copolymerization polyacrylamide (PAM) according to the properties of sludge is to match the dispersibility, bound-water proportion, surface characteristics, and viscosity of sludge particles. By balancing the "bridging ability" and "solution viscosity" of polyacrylamide PAM in wastewater uses agent molecular chains, efficient flocculation and dewatering can be achieved:

1. Sludge Concentration (SS, Suspended Solid Content) The sludge concentration directly determines the distance between particles and the difficulty of mixing, and is the primary basis for choosing the molecular weight:

Low Concentration Sludge

Characteristics: Particles are sparse, highly dispersed, and the distance between particles is large. Long molecular chains are required to "drag net" bridge to connect dispersed particles into flocs.

Suitable Molecular Weight of polyacrylamide polymer emulsion: High molecular weight (18 - 25 million).

Reason: Long chain copolymerization polyacrylamide can adsorb multiple particles across a larger distance, forming large and compact flocs (particle size 1-3mm), accelerating sedimentation or dewatering.

Medium Concentration Sludge (1% ≤ SS ≤ 5%, such as municipal mixed sludge)

Characteristics: The particle density is moderate, with both dispersed particles and a small number of natural aggregates. It is necessary to balance the bridging ability and solution fluidity. Suitable Molecular Weight of copolymerization polyacrylamide: Medium molecular weight (12-18 million).

Reason: Medium length chains can take into account both particle connection and uniform mixing, avoiding the high viscosity of high molecular weight of copolymerization polyacrylamide causing local "enclosure" (water trapped inside the flocs) or insufficient bridging of low molecular weight polyacrylamide PAM in wastewater uses. For municipal sludge (SS = 3%), using copolymerization polyacrylamide with a molecular weight of 15 million, the moisture content of the filter cake is 3%-5% lower than that of PAM with a molecular weight of 20 million.

High Concentration Sludge (SS > 5%, such as chemical sludge, paper - making sludge)

Characteristics: Particles are dense and highly viscous (similar to paste), and copolymerization polyacrylamide has difficulty penetrating into the interior, easily forming a "shell layer" on the surface (only the outer layer flocculates, and the internal water cannot be separated).

Suitable Molecular Weight of copolymerization polyacrylamide: Low molecular weight (8 - 12 million).

Reason: Short chain copolymerization polyacrylamide has a low viscosity (at the same concentration, the viscosity of 8 million molecular weight copolymerization polyacrylamide is only 1/3 of that of 20 million molecular weight PAM), which can quickly penetrate into the interior of the sludge, uniformly adsorb particles, and avoid surface enclosure. For a certain paper making sludge (SS = 6%), using PAM with a molecular weight of 10 million shortens the dissolution time by 50% and increases the dewatering efficiency by 20% compared with that of 18 million molecular weight polyacrylamide polymer emulsion.

2. Organic Matter Content (VS/TS Ratio)

The organic matter content reflects the proportion of biological flocs (such as EPS) in the sludge, directly affecting the surface characteristics of particles and the proportion of bound water:

High Organic Matter Sludge (VS/TS > 60%, such as excess activated sludge, municipal sludge)

Characteristics: It contains a large amount of extracellular polymers (EPS), with fine particles (particle size < 50μm), a high proportion of bound water (> 30%), strong negative charges on the surface, and is easy to disperse.

Suitable Molecular Weight of polyacrylamide polymer emulsion: Medium high molecular weight (15 - 22 million).

Reason: The "colloid barrier" formed by EPS requires long chain polyacrylamide polymer emulsion to penetrate. Through stronger bridging ability, the colloidal stability is broken, and fine particles are agglomerated into shear resistant flocs. For example, for municipal excess sludge (VS/TS = 70%), using cationic liquid flocculant with a molecular weight of 18 million (ionic degree 30%) and conditioning with PAC, the SS of the supernatant after centrifugal dewatering is reduced from 200mg/L to 80mg/L.

Low Organic Matter Sludge (VS/TS < 40%, such as inorganic sludge, grit chamber sludge)

Characteristics: It is mainly composed of inorganic particles (sand, soil, minerals), with coarse particles (particle size > 100μm), less bound water, weak surface charges, and is easy to settle naturally.

Suitable Molecular Weight of cationic liquid flocculant: Low medium molecular weight (8-15 million).

Reason: The particles themselves are easy to agglomerate, and do not require overly long molecular chains. The short chains of low medium molecular weight cationic liquid flocculant can achieve effective connection, and the low viscosity characteristic can avoid filter cloth blockage. For a certain mine sludge (VS/TS = 30%), using anionic liquid flocculant with a molecular weight of 10 million, the pressure filtration speed is 25% faster than that of 18 million molecular weight polyacrylamide PAM in wastewater uses.

3. Particle Size and Specific Surface Area The finer the particles and the larger the specific surface area, the longer the molecular chains needed to cover and connect the particles.

Fine Particle Sludge (particle size < 50μm, such as biochemical sludge, printing and dyeing sludge)

Characteristics: It has a large specific surface area (> 1000 cm²/g), high surface energy, and easily adsorbs water molecules to form a stable colloid. Strong bridging force is required to break the stability.

Suitable Molecular Weight of polyacrylamide polymer emulsion: Medium high molecular weight (15 - 20 million).

Coarse Particle Sludge (particle size > 100μm, such as grit chamber sludge, steel - making sludge)

Characteristics: It has a small specific surface area (< 500 cm²/g), and particles are easy to collide and agglomerate, with a low demand for bridging chain length.

Suitable Molecular Weight of polyacrylamide polymer emulsion: Low-medium molecular weight (8 - 15 million).

4. pH Value and Ionic Environment

The pH value and ionic strength of the sludge will affect the dissolution, charge stability, and adsorption ability of polyacrylamide polymer emulsion, indirectly affecting the selection of molecular weight.

Strongly Acidic Sludge (pH < 4, such as chemical pickling sludge)

Characteristics: The H⁺ concentration is high, which may cause the hydrolysis of anionic PAM (molecular chain breakage), and cationic liquid flocculant is more stable in an acidic environment.

Suitable Molecular Weight of polyacrylamide polymer emulsion: Medium molecular weight (12 - 16 million) (to avoid the chain breakage and failure of high molecular weight cationic liquid flocculant in an acidic environment).

Reason: Medium length chains are more stable in an acidic environment and can meet the basic bridging requirements at the same time.

Strongly Alkaline Sludge (pH > 10, such as lime - conditioned sludge)

Characteristics: OH⁻ will enhance the rigidity of sludge particles (such as Ca(OH)₂ particles formed by lime), and long chain polyacrylamide PAM in wastewater uses is needed to connect dispersed rigid particles.

Suitable Molecular Weight: High molecular weight (20 - 25 million).

High Salt Sludge (such as desalination sludge, pickled wastewater sludge)

Characteristics: High ionic strength compresses the double electric layer, particles are easy to agglomerate but the flocs are loose, and an appropriate chain length is needed to enhance the floc strength.

Suitable Molecular Weight of cationic liquid flocculant : Medium molecular weight (12 - 18 million) (to avoid the abnormal increase in viscosity of high molecular weight cationic liquid flocculant due to salting out).

Industry-specific attributes:

| Name | Cationic liquid flocculant | |||

| Application | Polyacrylamide PAM in wastewater uses | |||

| CAS NO. | 9003-05-8 | |||

Other Attributes:

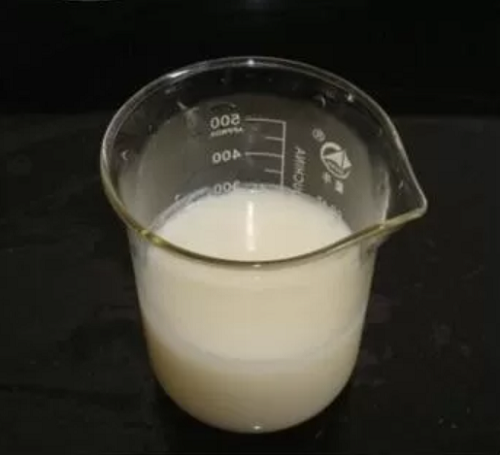

| Appearance | Polyacrylamide polymer emulsion | |||

| Activate Content | 48% | |||

| Viscosity Range(ml/g) | 1200~1600 | |||

| Residue | 0.12% | |||

| Insoluble Substance(%) | 0.1 | |||

| Cationic Charge | 80% | |||

| Dissolving Time,min | 40 | |||

| Storage Temperature,℃ | 0~35 | |||

| Shelf Life,month | 12 | |||

Supply Ability:

| Supply Ability | 2000Metric Tons per Month | |||

Lead Time:

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |