Cationic Polyacrylamide Powder For Sewage Treatment

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 2000Metric Tons per Month

1. Cationic polyacrylamide polymer is used in the dewatering process in the STP.

2. Cationic polyacrylamide for sewage treatment has a variety of cationic charges to meet the dewatering process.

3. Customized polyacrylamide is our company's advantage. Based on the parameters the clients provided, we can produce the

equivalent products(SNF&BASF Polyacrylamide)

Download

Cationic polyacrylamide powder, also named cationic polyacrylamide polymer, is widely used in the dewatering process in polyacrylamide sewage treatment.

Polyacrylamide sewage treatment is able to meet variety of types of dewatering machines on the site.

Cationic polyacrylamide polymer JF series(JF9170) has a complete product line to meet various dewatering machines in STP. Due to different running theories, cationic polyacrylamide for sewage treatment needs to meet different dewatering machines. Such as: High shear - resistance products are suitable for centrifuge.

Cationic polyacrylamide for sewage treatment (solid PAM domestic water) is a kind of polymer made from acrylamide after polymerization with DAC or DMC.

The chemical formula of cationic polyacrylamide polymer for sewage is (C3H5NO)n and cationic polyacrylamide polymer's appearance is pure white powder.

The content of solid PAM domestic water cationic polyacrylamide is 90%, the molecular weight is 8~9,the specific granvity is 0.75 and the pH value (1% aqueous solution) is 6.0~8.0

To dissolve the solid PAM domestic water product such as BASF polyacrylamide & our products, a special device is needed to do it.

Cationic polyacrylamide for sewage treatment produced by our company can rival world - famous brand products, and is equivalent to polyacrylamide from SNF & BASF. We have a strong technical database which can search the parameters of polyacrylamide that the clients need.

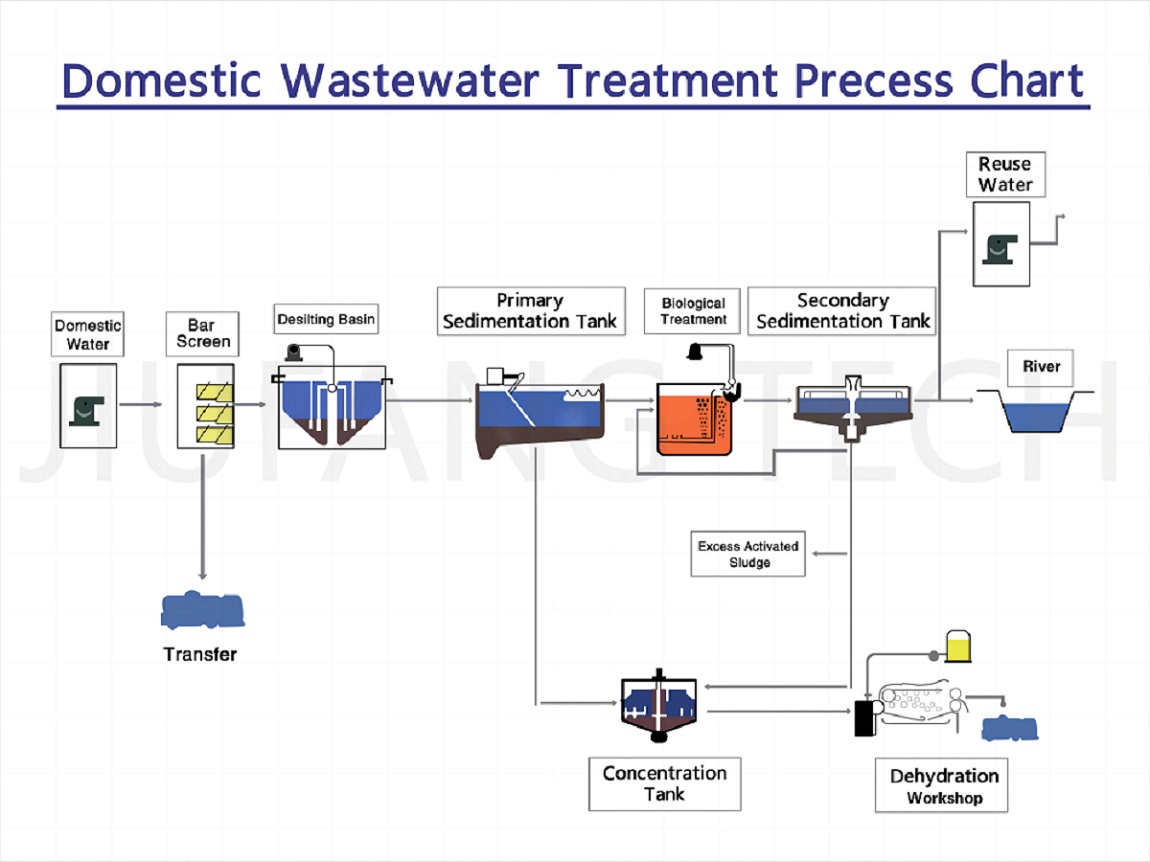

Municipal sludge: Excess activated sludge and digested sludge from urban sewage treatment plants (with a high proportion of organic components and strong colloidal stability). Industrial organic sludge: Such as sludge generated in industries like printing and dyeing, food processing, pharmaceuticals, and papermaking (containing a large amount of microorganisms and organic matter, with a significant negative charge). High - moisture - content sludge: Primary sedimentation sludge and excess sludge (the moisture content is usually between 95% - 99%, and the water - binding force needs to be reduced through CPAM flocculation). For inorganic sludge (such as metallurgical and mining sludge), due to the relatively weak negative charge of colloidal particles, anionic or non - ionic polyacrylamide may be more suitable. However, some mixed sludge (organic + inorganic) can also be adapted by adjusting the CPAM model.

Industry-specific attributes

Industry-specific attributes

| Name | Polyacrylamide (Equivanlent BASF polyacrylamide) | |||

| Chemical Formula | (C3H5NO)n | |||

| CAS NO. | 9003-05-8 | |||

Other Attributes

| Appearance | White Powder | |||

| Solid Content | 90% | |||

| Molecular Weight 10*6 | 8~9 | |||

| Density(25℃) | 0.75g/cm3 | |||

| PH Value(1% water solution) | 6~8 | |||

| Cationic Charge | 70% | |||

| Dissolving Time,min | <30 | |||

| Storage Temperature,℃ | 0~35 | |||

| Shelf Life,month | 24 | |||

Supply Ability

| Supply Ability | 2000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |