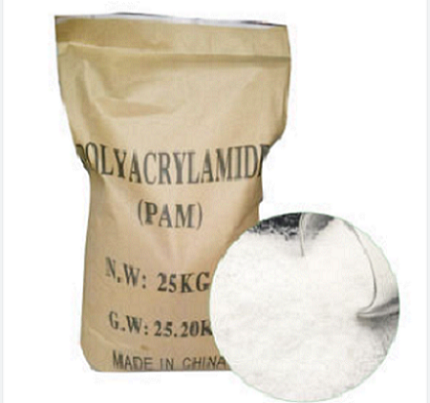

Cationic Polyacrylamide Powder For Water Treatment

Brand Jiufang

Product origin Shenyang City,China

Delivery time Negotiable

Supply capacity 2000tons per month

Cationic polyacrylamide is made by DAC or DMC copolymerized with acrylamide which is a white powder product.

Polyacrylamide powder for industrial water treatment or CPAM solid in oilfield need two types of polymer: cationic polyacrylamide powder and anionic polyacrylamide powder.

Download

As an important chemical agent in oilfield development, cationic polyacrylamide (CPAM) powder, with cationic polyacrylamide high molecular weight, controllable charge density, and unique powder form, exhibits significant advantages in various processes such as drilling, oil production, profile control and water shut-off, and oilfield wastewater treatment.

The usage characteristics of cationic polyacrylamide can be summarized in combination with specific oilfield application scenarios as follows:

1.High-efficiency Flocculation and Adsorption

The cationic groups (such as amino groups) on the molecular chain of cationic polyacrylamide for water use powder can undergo charge neutralization and bridging adsorption with negatively - charged substances in the oilfield system (such as clay particles, crude oil emulsions, suspended solids in wastewater), forming stable flocs. Example: In drilling fluids, CPAM solid in oilfield can quickly flocculate rock cuttings and colloidal particles in the drilling fluid, reducing viscosity and maintaining the fluidity of the drilling fluid. In oilfield wastewater treatment, cationic polyacrylamide for water use can efficiently remove crude oil and suspended solids from the water, enabling the water to meet the standards for recycling.

2. Temperature and Salt Resistance (Requires Targeted Modification)

Ordinary cationic polyacrylamide powder for industrial water is prone to molecular chain breakage or charge shielding in high-temperature (>80℃) and high-salt (salinity > 10⁴mg/L) reservoirs, resulting in a decline in performance. However, cationic polyacrylamide powder for industrial water modified by introducing salt-resistant monomers (such as acrylamidopropyltrimethylammonium chloride) can maintain stable thickening and adsorption properties in high-temperature and high-salt environments, making it suitable for complex reservoirs such as deep wells and offshore oilfields.

3. Adjustability of Molecular Weight and Charge Density

The product of cationic polyacrylamide for water use can adjust the molecular weight (from several million to tens of millions) and charge density (10%--80%) through the polymerization process to meet the needs of different scenarios:

High molecular weight and low charge density: Suitable for oil-displacement thickening in tertiary oil recovery (increasing the viscosity of injected water and expanding the swept volume).

Low molecular weight and high charge density: Suitable for profile control and water shut - off (quickly adsorbing on the surface of rocks in high - permeability layers to form a blockage).

Cationic polyacrylamide powder product is always used for CPAM solid in oilfield,cationic polyacrylamide is also applied for produced water pretreatment use CPAM solid in oilfield and be used for dewatering in refineries.

Industry-specific attributes

| Name | Cationic Polyacrylamide powder | |||

| Application | Cationic polyacrylamide for water uses | |||

| CAS NO. | 9003-05-8 | |||

Other Attributes

| Appearance | White Powder | |||

| Solid Content | 90% | |||

| Molecular Weight 10*6 | 8~9 | |||

| Density(25℃) | 0.75g/cm3 | |||

| PH Value(1% water solution) | 6~8 | |||

| Cationic Charge | 70% | |||

| Dissolving Time,min | <30 | |||

| Storage Temperature,℃ | 0~35 | |||

| Shelf Life,month | 24 | |||

Supply Ability

| Supply Ability | 2000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |