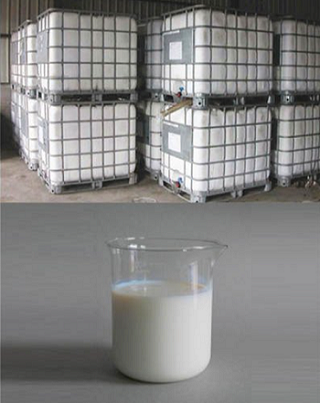

CPAM Emulsion For wastewater Treatment

Brand JF

Product origin China

Delivery time Lead time: 7days

Supply capacity 10000MT/Year

1.Every month our factory could produce 2000tons CPAM liquid and liquid CPAM product is a cross linked polymer.

2.We have cooperated with more than 300 clients in CPAM for water treatment project.

3.We own dozens of outstanding engineer and customized products could be supplied in emulsion CPAM water treatment.

Download

The flocculation effect of Cross linked CPAM liquid ationic is the result of its interaction with pollutants in sewage, such as colloidal particles, crude oil emulsions, and suspended solids. It is influenced by various factors including the properties of the agent itself, the environmental parameters of the sewage, and the operating conditions.

The specific influencing factors are as follows:

1. Properties of the CPAM for water treatment agent

The molecular structure and physicochemical properties of CPAM liquid is the basis for determining flocculation effect of CPAM liquid, mainly including the following parameters:

1). Cross linking Degree of CPAM liquid

The cross-linking degree refers to the density of cross-linking bonds between molecular chains, directly affecting the compactness of the three-dimensional network structure.

If the degree of CPAM liquid is too low: The three - dimensional structure is loose, with poor mechanical strength and weak shear resistance. It is prone to breakage under high-flow or stirring conditions, resulting in a decrease in bridging ability and easy breakage of flocs.

If the cross-linking degree is too high: The molecular chain of CPAM liquid becomes too rigid, and its solubility decreases (it may even be difficult to dissolve). It cannot be fully dispersed in the sewage to contact pollutants, and an overly dense network structure may hinder the encapsulation and adsorption of colloidal particles, leading to a reduction in flocculation efficiency.

2). Cationic Degree of CPAM liquid

The cationic degree of CPAM liquid determines the charge-neutralizing ability and directly affects the adsorption efficiency of negatively-charged pollutants (such as crude oil emulsions, clay particles).

3). Molecular Weight of CPAM liquid

The molecular weight of CPAM liquid affects the length of the molecular chain and the steric hindrance effect.

When the molecular weight is large: The chain of CPAM liquid is longer, and the bridging ability is stronger, which can connect more colloidal particles to form large flocs. However, an overly high molecular weight may lead to a decrease in solubility, and it is prone to breakage in a high-shear environment.

When the molecular weight is small: The chain of CPAM liquid is short, the bridging ability is weak, the flocs are small, and the sedimentation is slow.

In practical applications, a matching molecular weight (usually between 1 million-10 million) needs to be selected according to the sewage flow rate (shear strength) and the particle size of pollutants.

2. Sewage Water Quality Parameters

Oilfield sewage has a complex composition (containing oil, suspended solids, high salinity, high temperature, etc.), and its water quality characteristics directly affect the interaction between CPAM liquid and pollutants:

1). pH Value: The pH value affects the dissociation degree of CPAM liquid groups and the surface charge of pollutants, thus changing the flocculation effect

2). Temperature: Temperature affects the molecular mobility and structural stability of CPAM liquid:

At low temperatures (<20℃): The molecular chain of CPAM liquid moves slowly, the probability of collision with pollutants decreases, the flocculation reaction rate slows down, and the time for floc formation is prolonged.

At high temperatures (>80℃): Although it can accelerate molecular movement, it may cause partial degradation of the cross - linked structure of CPAM liquid(especially when the cross - linking bonds are weak), destroying the three-dimensional network structure and reducing the shear resistance.

At the same time, high temperatures may make the crude oil emulsion more stable, increasing the difficulty of flocculation. - Adaptability: For deep - well sewage in oilfields (60 - 120℃), high-temperature - resistant cross - linkers (such as CCPAM cross - linked with epichlorohydrin) need to be selected to avoid structural failure at high temperatures.

3). Salinity (Ionic Strength) : Oilfield sewage contains high concentrations of Na⁺, Ca²⁺, Mg²⁺, Cl⁻, etc.

4). Pollutant Type and Concentration-Surface charge of pollutants: The adsorption ability of CPAM liquid to crude oil emulsions (strongly negatively charged), clay particles (negatively charged), and bacterial debris (negatively charged) in oilfield sewage is different.

3. Operating Process Conditions The operating parameters of the flocculation process directly affect the dispersion, reaction, and floc formation of CPAM liquid:

1). Dosage: The dosage is a key factor affecting the flocculation effect:

Insufficient dosage: It cannot fully neutralize the charges of pollutants or bridge, resulting in small flocs, high turbidity, and high oil content in the effluent.

Excessive dosage: Excessive CPAM liquid molecules are adsorbed on the surface of particles, forming a "positive-charge encapsulation". Particles re-disperse due to the repulsion of the same charge (i.e., "re - stabilization"), and at the same time, it increases the cost of the agent and the COD of the effluent.

Optimal dosage: It needs to be determined through jar tests. Usually, for oilfield sewage, it is 5 - 50 mg/L (specifically adjusted according to the pollutant concentration and the performance of CPAM liquid).

2). Stirring Intensity and Time - The purpose of stirring is to evenly disperse CPAM liquid and make it fully contact with pollutants, but the intensity and time need to be controlled:

Mixing stage (1 - 5 minutes after dosing): Medium - to - high - intensity stirring (rotation speed 100 - 300 r/min) is required to ensure uniform dispersion of the agent and avoid excessive local concentration.

Flocculation stage (5 - 20 minutes after mixing): Low - intensity stirring (rotation speed 30 - 60 r/min) is required to promote the growth of flocs and avoid strong shear from breaking the formed flocs.

Insufficient stirring: The agent is unevenly dispersed, resulting in over flocculation in some areas and insufficient reaction in others.

Excessive stirring: The flocs are broken, and the sedimentation performance deteriorates.

3). Dosing Method - CPAM liquid needs to be prepared into an aqueous solution of a certain concentration (usually 0.1% - 0.5%) before dosing. Direct addition of solids should be avoided to prevent caking ("fish - eyes"), which affects dissolution and reaction. If step - by - step dosing (first adding a low - concentration solution and then replenishing after a certain interval) is adopted, the risk of "re - stabilization" can be reduced, and the flocculation efficiency can be improved.

4. Interference of Co - existing Substances

There may be other agents (such as demulsifiers, bactericides) or impurities in oilfield sewage, affecting the flocculation effect of CPAM liquid:

Synergistic effect: When used in combination with inorganic flocculants (such as PAC, FeCl₃), the inorganic agents first compress the double-electric layer, and then CPAM liquid plays a bridging role, which can improve the flocculation efficiency (for example, the "PAC + CCPAM" combination is commonly used in oilfield sewage).

Interference effect: If there are excessive anionic agents (such as anionic demulsifiers, sodium polyacrylate) in the sewage, they may react with the cationic groups of CPAM liquid to form precipitates, consuming the effective agent. In addition, reducing substances such as sulfides (S²⁻) and humic acid may destroy the cross - linked structure of CPAM liquid, reducing its stability.

The flocculation effect of cross - linked cationic polyacrylamide is the result of the combined action of the properties of the agent itself (cross - linking degree, cationic degree, molecular weight), the sewage water quality (pH, temperature, salinity, pollutant characteristics), operating conditions (dosage, stirring, dosing method), and co-existing substances.

In practical applications (such as oilfield sewage treatment), key parameters need to be optimized through small - scale and pilot - scale tests to balance the influence of various factors, so as to achieve efficient flocculation (such as oil content in the effluent < 10 mg/L, suspended solids < 20 mg/L).

Industry-specific attributes

| Name | CPAM liquid | |||

| Application | CPAM for water treatment | |||

| CAS NO. | 9003-05-8 | |||

Other Attributes

| Appearance | White Emulsion | |||

| Activate Content | 48% | |||

| Viscosity Range(ml/g) | 1200~1600 | |||

| Residue | 0.12% | |||

| Insoluble Substance(%) | 0.1 | |||

| Cationic Charge | 80% | |||

| Dissolving Time,min | 40 | |||

| Storage Temperature,℃ | 0~35 | |||

| Shelf Life,month | 12 | |||

Supply Ability