CPAM Powder For Oily Sludge Treatment

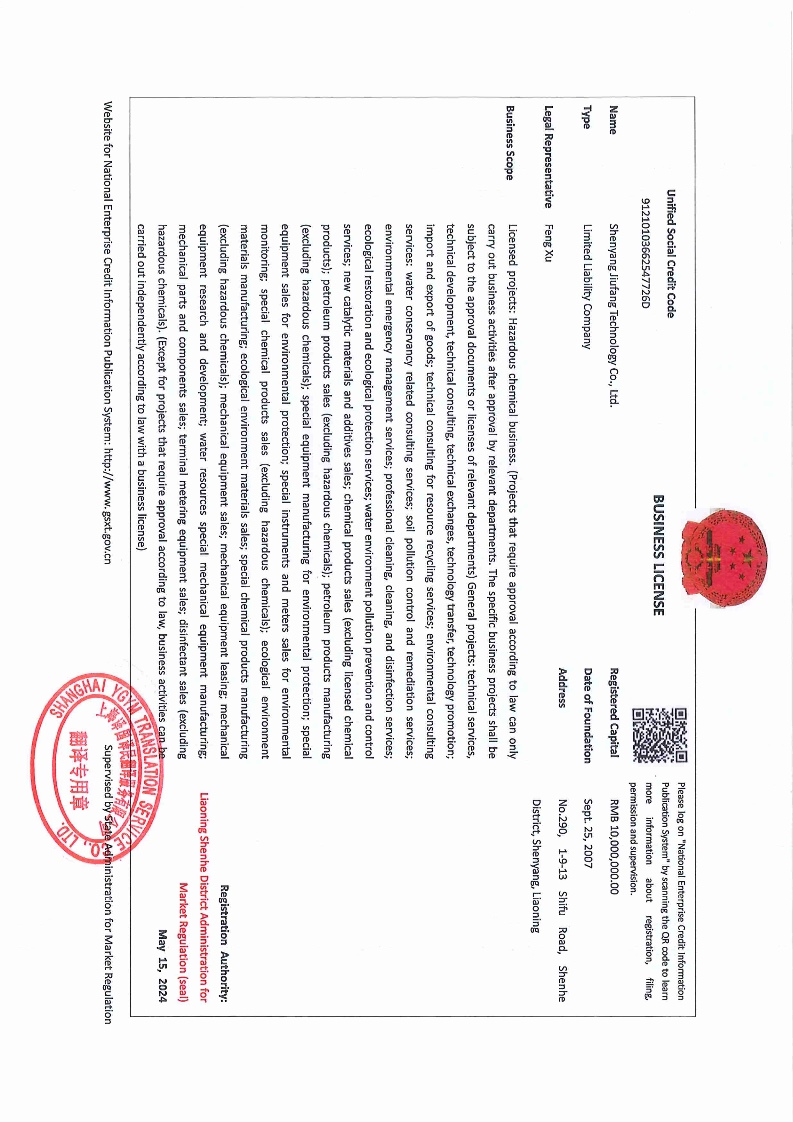

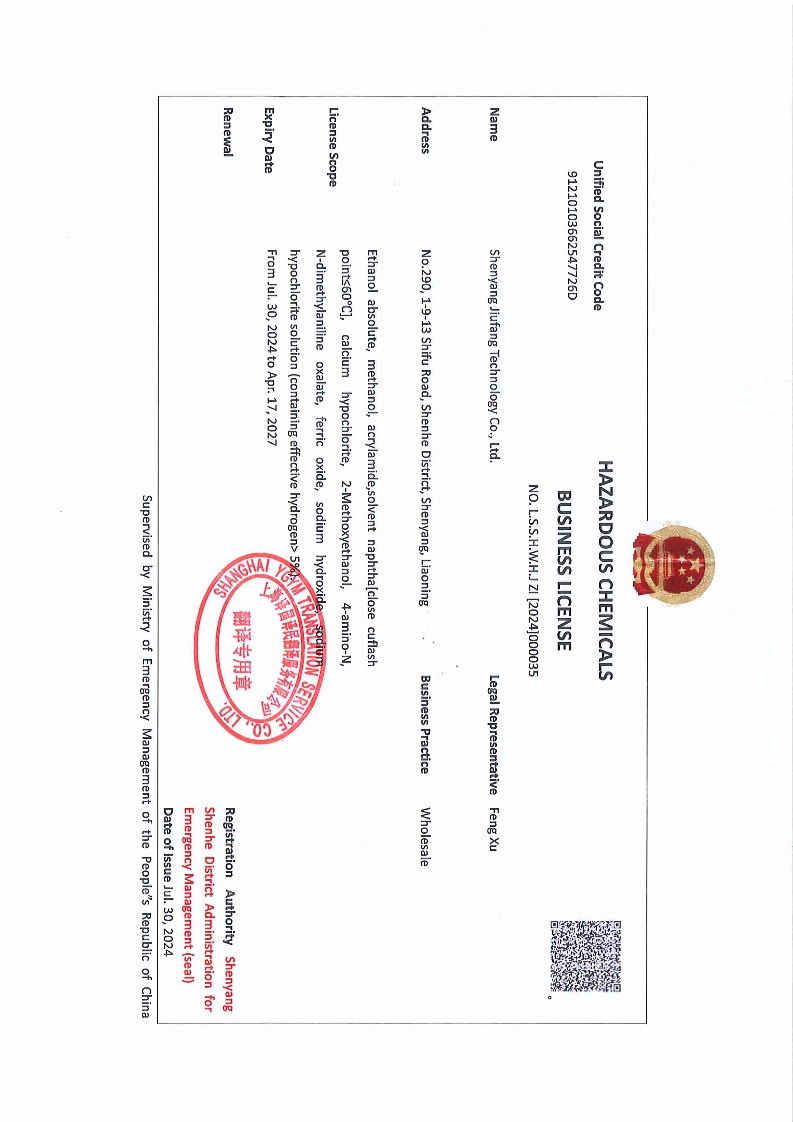

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 2000Metric Tons per Month

1.Oily sludge by powder CPAM is the scum from DAF treated water that is treated with cationic polyacrylamide flocculant.

2. Powder CPAM sludge treatment is used in pretreatment process in the oilfield.

3. Sludge by powder CPAM, especially oil sludge by powder CPAM is a comprehensive solution.

Download

Compared with other types of cationic polyacrylamide flocculant (such as inorganic flocculants, anionic polyacrylamide (APAM), non-ionic polyacrylamide (NPAM), etc.), cationic polyacrylamide flocculant (CPAM) has unique advantages in sludge reduction, which mainly stem from its adaptability to sludge characteristics and high-efficiency flocculation and dewatering capabilities.

The specific advantages of powder CPAM for sludge treatment agents are as follows:

1.Stronger Charge Compatibility, Adapting to the Negative-Charge Characteristics of Sludge

The colloidal particles in sludge, such as bacteria and organic matter fragments, usually have a negative charge on their surface, and the negative charge density is relatively high. The cationic groups (such as quaternary ammonium groups) on the sludge CPAM molecular chain can directly neutralize the charge with the negative charges of the sludge particles, quickly eliminating the electrostatic repulsion between particles and promoting flocculation.

In contrast, anionic polyacrylamide (APAM) has a negative charge and will repel the sludge particles. It is only applicable to specific sludges with high positive charges. Non-ionic polyacrylamide (NPAM) has no charge and relies only on the bridging effect of the molecular chain, resulting in a much lower flocculation efficiency than sludge CPAM.

Inorganic flocculants (such as PAC, ferric chloride) can neutralize charges, but their charge density is low and the action range is limited, so they have a poor effect on high-negative - charge sludges.

2. More Stable Floc Structure, Superior Dewatering Performance

The core of sludge reduction is to reduce the water content (from 95%-99% to 60%-80%), and the dewatering efficiency depends on the structural strength of the sludge CPAM.

Based on charge neutralization, the long-chain molecules of powder CPAM for sludge agent connect multiple particles into large, compact flocs with a reasonable pore structure through the "bridging effect". These flocs have high mechanical strength and strong shear resistance. They are not easily broken during mechanical treatments such as plate and frame filtration and centrifugal dewatering, and can efficiently encapsulate free water and interstitial water for rapid separation.

The flocs formed by inorganic flocculants are usually loose and fragile (for example, the flocs formed by PAC have a high water content and large compressibility), and the water content of the filter cake after dewatering is still relatively high (usually>80%). Although the flocs formed by APAM or NPAM are relatively large, due to the lack of charge neutralization, their structural stability is poor, and they are prone to "redissolution" during dewatering, resulting in a large amount of residual water.

3. Lower Dosage, Higher Reduction Efficiency

As a cationic polyacrylamide flocculant, powder CPAM for sludge treatment agent usually has a molecular weight between 1 million and 10 million. A single molecular chain can bridge a large number of particles, and the targeting of the cationic groups is strong. Therefore, the dosage per unit of sludge is much lower than that of inorganic flocculants (usually 1/10-1/100 of that of inorganic flocculants). For example, to treat 1 ton of municipal sludge, the dosage of powder CPAM sludge treatment agent may only need 0.1 -1 kg, while that of PAC may need 5-20 kg.

The low dosage not only reduces the cost of the agent but also decreases the "newly added solids" introduced by excessive agents (such as the salt residues of inorganic flocculants), avoiding the "rebound" of the sludge volume and truly achieving high-efficiency reduction.

4. Wider Application Range, Especially for Hard -to -Dewater Sludge

The dewatering difficulty of sludge is closely related to its organic matter content and viscosity (such as excess activated sludge, digested sludge, etc., which have a high organic matter content and high viscosity and belong to hard - to - dewater sludge).

Sludge CPAM has a strong adaptability to hard-to-dewater sludges with high organic matter and high negative charges. Its cationic groups can bind to the negatively charged groups (such as carboxyl and hydroxyl groups) of organic matter (such as proteins and polysaccharides). At the same time, the long-chain molecules can penetrate the viscous sludge colloid layer to strengthen flocculation. Inorganic flocculants have a poor effect on such sludges (easily being encapsulated and inactivated by organic matter), and APAM/NPAM, due to the lack of charge action, have limited effects in breaking the colloidal stability of sludge, resulting in limited reduction effects.

5. Reducing the Subsequent Treatment Load, Strengthening Terminal Reduction

The sludge filter cake treated sludge by powder CPAM has the characteristics of low water content, small volume, and high firmness:

During transportation, the number of trips can be reduced (for example, when the water content is reduced from 90% to 70%, the volume is reduced by about 60%).

In landfilling, it saves storage space. In incineration, it reduces energy consumption (for every 10% reduction in water content, the calorific value of incineration increases by about 15%). In composting, it shortens the maturation cycle (reducing the inhibition of water on microbial activity). In contrast, the sludge treated by inorganic flocculants often has increased subsequent disposal difficulties (such as the corrosion of the landfill impermeable layer and the scaling of the incinerator) due to residual salts or loose structures.

The core advantages of CPAM in sludge reduction stem from its charge targeting, high-efficiency flocculation ability, and wide adaptability to sludge characteristics. Especially in terms of reducing water content, decreasing volume, and improving subsequent treatment efficiency, it is significantly superior to inorganic flocculants and other types of polyacrylamide. It is currently the most widely used high-efficiency flocculant in municipal and industrial sludge reduction.

Industry-specific attributes

| Name | Cationic polyacrylamide flocculant | |||

| Application | Powder CPAM for sludge treatment | |||

| CAS NO. | 9003-05-8 | |||

Other Attributes

| Appearance | Powder CPAM for sludge | |||

| Solid Content | 90% | |||

| Molecular Weight 10*6 | 8~9 | |||

| Density(25℃) | 0.75g/cm3 | |||

| PH Value(1% water solution) | 6~8 | |||

| Cationic Charge | 70% | |||

| Dissolving Time,min | <30 | |||

| Storage Temperature,℃ | 0~35 | |||

| Shelf Life,month | 24 | |||

Supply Ability

| Supply Ability | 2000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |