Reverse demulsifier function

Brand Shenyang Jiufang

Product origin China

Delivery time Lead time: 7days

Supply capacity 10000MT/Year

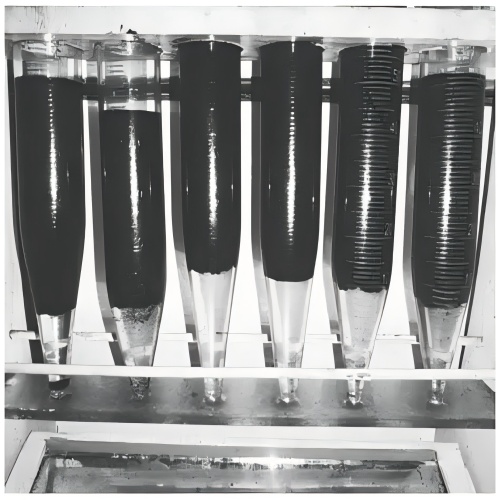

The function of reverse demulsifier is used for breaking oil in water emulsions.

Reverse Demulsifier application is in the oilfield, refinery and some plants where the produced water contains oil.

Reverse demulsifier in refinery and in oilfield is the comprehensive solution that treat the oily wastewater and sludge.

Download

The function of reverse demulsifier is as the following:

1.Oil-water separation In oily sewage, reverse demulsifier can prompt the rapid separation of oil and water. Reverse demulsifier achieves this by destabilizing the oil-water interface, causing the originally emulsified oil droplets to aggregate and float, while the water becomes clarified. This is of great significance for treating industrial oily wastewater and produced water from oil fields, as it can effectively reduce the oil content in water and meet environmental protection discharge requirements.

2.Improving water quality Removing oil pollutants: Reverse demulsifier can coagulate tiny oil droplets into larger oil beads, making them easier to separate from water, thereby significantly reducing the oil concentration in water and improving the cleanliness of water. Reducing suspended solids: During the process of oil separation, some suspended solids bound to the oil droplets are often separated together, further purifying the water quality and creating favorable conditions for subsequent water treatment processes or water reuse.

3. Reducing treatment costs by the function of reverse demulsifier Reducing the dosage of reverse demulsifier: Compared with traditional water treatment methods, the usage amount of reverse demulsifier is relatively small, yet it can achieve efficient oil-water separation effects, thereby reducing reverse demulsifier application costs. Simplifying the treatment process: The rapid demulsification effect of reverse demulsifier application can reduce treatment links and equipment investment. For example, the function of reverse demulsifier can reduce the volume of sedimentation tanks or the frequency of using filtration equipment, lowering infrastructure construction and operation and maintenance costs.

4. Wide reverse demulsifier application range Reverse demulsifier application in different industries: The function of reverse demulsifier can be widely used in the treatment of oily wastewater in industries, such as reverse demulsifier in refinery, petrochemical, steel, mechanical processing and food processing and has good demulsification effects on various types of emulsified oil. Various water quality conditions: Whether it is high-concentration oily wastewater or low-concentration oily wastewater, reverse demulsifier can play a role. At the same time, reverse demulsifier in refinery also has certain adaptability to water quality with different pH values, temperatures, and salinities.

There are several taboos when using reverse phase demulsifier in refinery:

1. Avoid mixing with incompatible chemicals They should not be randomly mixed with other types of reverse demulsifier or chemical agents, as chemical reactions may occur between different agents, resulting in reduced demulsification effects or even the generation of harmful substances. For example, the mixture of certain cationic demulsifiers with anionic reverse phase demulsifiers may form precipitates, affecting the performance of the agents. Before using reverse demulsifier, it is important to read the reverse demulsifier COA in order to learn more details about the function of reverse demulsifier and reverse demulsifier application.

2. Strictly control the usage conditions Temperature aspect: They should be used within an appropriate temperature range. Excessive high or low temperatures may affect the performance of the reverse demulsifier. If the temperature exceeds the recommended range, it may reduce the activity of the reverse demulsifier and prevent them from effectively destroying the oil-water interface film, thereby reducing the demulsification effect. pH value limitations: Different reverse demulsifier have certain requirements for pH values. They should not be used in an unsuitable pH environment. Strong acid or strong base conditions may cause the reverse demulsifier to decompose or lose activity, preventing them from performing the demulsification function normally.

3. Prevent excessive usage Do not add excessive reverse demulsifier. Excessive usage not only increases costs but may also cause changes in water quality, resulting in new pollution problems or adverse effects on subsequent treatment processes.

4. Pay attention to storage conditions Sealed storage: Reverse demulsifier should be stored in a sealed manner to avoid contact with air and moisture, preventing the agent from getting damp or oxidizing and deteriorating. If the recerse demulsifier are exposed to air, they may absorb moisture and agglomerate, affecting their solubility and usage effects. Stay away from fire sources and heat sources: The storage site should be kept away from fire sources and heat sources to prevent fires or thermal decomposition of the agent. Some reverse demulsifier may lose activity or undergo dangerous chemical reactions at high temperatures.