Chemical Polydadmac For Water Treatment

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 1000Metric Tons per Month

40%chemical polydadmac emulsion has been widely applied as a polydadmac coagulant in drinking water and sewage treatment.

Chemical polydadmac products are a high molecular weight product and are 40%polydadmac chemicals (Polydadmac 40).

Download

The molecular weight of 40% chemical polydadmac emulsion is a core indicator determining the application performance of polydadmac 40, directly influencing the physical and chemical properties of the polydadmac chemicals products (such as charge density, water-solubility, viscosity) and practical functions of polydadmac coagulant (such as flocculation efficiency, film-forming ability, adsorption capacity).

Polydadmac 40 with different molecular weights exhibits significant differences in application scenarios, and the significance of molecular weight of 40% chemical polydadmac emulsion is mainly reflected in the following aspects:

1. Influence on Flocculation and Water Treatment Performance

As a cationic polymer polydadmac coagulant, polydadmac 40 is widely used in the treatment of municipal sewage and industrial wastewater (such as printing and dyeing, papermaking wastewater).

The molecular weight of polydadmac chemicals is the key to determining the flocculation efficiency:

High-molecular-weight polydadmac 40 (1,000,000-5,000,000): The molecular chain of polydadmac chemicals is long and has good extensibility. Polydadmac 40 can adsorb and entangle multiple colloidal particles (such as suspended solids and colloidal particles in sewage) into clusters through the "bridging effect", forming large and dense flocs with a fast sedimentation rate. Polydadmac 40 is suitable for treating high-turbidity wastewater (such as mineral processing wastewater, slurry water). For example, polydadmac 40 with a molecular weight of 2,000,000 can achieve a COD (chemical oxygen demand) removal rate of over 80%, while a product with a molecular weight of 500,000 can only reach 50%-60%.

Medium and low-molecular-weight Polydadmac 40(100,000-1,000,000): The molecular chain of chemical polydadmac products are shorter, and the charge density is relatively higher (more cationic groups per unit length). It is more likely to adsorb negatively-charged fine particles (such as bacteria, colloidal impurities) through the "electro - neutralization effect". It is suitable for treating low-turbidity wastewater (such as drinking water pretreatment, electrophoretic wastewater), avoiding the formation of overly fine flocs that are difficult to sediment due to excessive use.

2. Compatibility with the Papermaking and Textile Industries In the papermaking and textile fields, polydadmac 40 is mainly used as a strengthening agent, retention aid, or softener.

The molecular weight determines its mode of binding to the substrate:

Papermaking Industry: Medium molecular weight of polydadmac 40 (500,000-1,500,000): The length of the molecular chain is moderate. It can form hydrogen bonds with the hydroxyl groups on the surface of pulp fibers (cellulose) and also adsorb fibers through cationic groups, improving the tensile strength and burst resistance of paper (the strengthening effect is 30%-50% higher than that of low-molecular-weight products).

Low molecular weight of polydadmac 40 (<500,000): It is more likely to penetrate into the interior of fibers. As a retention aid, it can reduce the loss of fillers (such as calcium carbonate), but the strengthening effect is weak.

Textile Industry: - Low molecular weight of polydadmac 40 (100,000-300,000): The short molecular chain is easy to be evenly adsorbed on the surface of fibers (such as cotton, polyester), forming a cationic protective layer, increasing the dye uptake rate (20%-40% higher than that of untreated fibers), and at the same time endowing the fabric with certain antibacterial properties.

3. Influence on the Oil Extraction and Daily Chemical Fields

Oil Extraction: As a drilling fluid additive or oil-displacement agent, high-molecular-weight of polydadmac 40 PDMDAAC (2,000,000-3,000,000) can improve the sand-carrying capacity of the drilling fluid through thickening, and its cationic property can stabilize the wellbore (inhibiting clay swelling). If the molecular weight is too high (>5,000,000), it will cause an abnormal increase in the viscosity of the drilling fluid, increasing pumping energy consumption.

Daily Chemical Field: In shampoos and conditioners, low-molecular-weight ofpolyacrylamide 40 PDMDAAC (50,000-200,000) can be adsorbed on the negatively-charged hair surface through cationic groups, forming a protective film, reducing frizz and enhancing smoothness (if the molecular weight is too high, it will make the hair stiff).

3. Influence on Product Stability and Processability

Water-solubility: 40% chemical polydadmac emulsion PDMDAAC is a water-soluble polydadmac coagulant. However, when the molecular weight of polydadmac 40 is too high (>5,000,000), high - concentration solutions (such as above 30%) are likely to form gels, which is not conducive to storage and transportation.

Medium and low-molecular-weight products can be prepared into higher concentration (40% - 50%) solutions with good fluidity.

Molecular Weight Distribution: In addition to the absolute molecular weight, the molecular weight distribution (MWD) is also important. Products with a narrow distribution (dispersion index < 2) have more stable performance (such as uniform floc size during flocculation), while products with a wide distribution may have excessive residual monomers due to low-molecular-weight components or poor solubility due to high-molecular-weight components.

The molecular weight of polydadmac 40 PDMDAAC needs to be "custom-made" according to specific application scenarios:

high-molecular-weight products of polydadmac coagulant focus on macroscopic effects such as flocculation and thickening, while medium and low-molecular-weight products focus on microscopic functions such as charge adsorption and penetration.

In industrial production, precise control of the molecular weight can achieve an optimal balance among efficiency, cost, and stability, which is the core reason why it can be widely used in multiple fields such as water treatment, papermaking, and oil extraction.

40%polydadmac and 50%polymine products always used for industrial wastewater and sewage treatment.

Industry-specific attributes

| Name | Polydadmac 40 chemical polydadmac products | |||

| Molecular Formula | (C8H16NCl)n | |||

| Application | Water Treatment | |||

Other Attributes

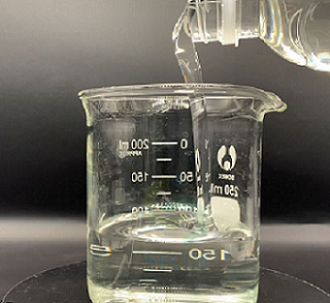

| Appearance | Colorless to white liquid,transparent | |||

| Odor | Odorless | |||

| Content | 40% | |||

| Viscosity,cPs | 6000~100000 | |||

| PH Value | 5~8 | |||

| Shelf life | 24 months | |||

Supply Ability

| Supply Ability | 1000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |