Chemical Demulsifier For Oilfield

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 1000Metric Tons per Month

1.Our factory could customize production of oilfield use demulsifier (F46 demulsifier).

2.Through efficient chemical demulsifiers, the recovered oil can be reprocessed and utilized, which can bring direct economic benefits. .

3.Our team own dozens of outstanding engineers and customized products(Oil demulsifier) could be supplied to the clients.

Download

Chemical demulsifiers(Oilfield use demulsifier) have extensive and important applications in oilfields.

During the oilfield exploitation process, crude oil often forms emulsions, causing difficulties in processing and transportation.

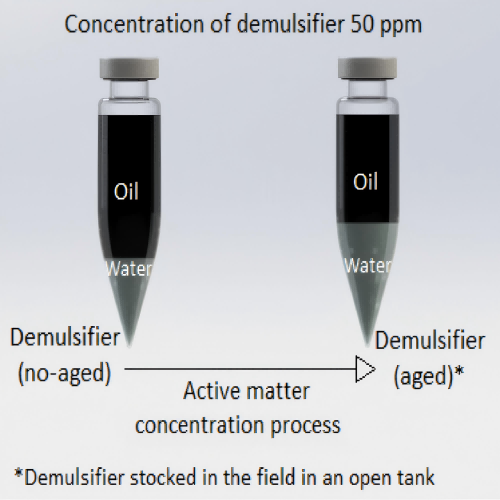

To achieve oil-water separation, F46 demulsifier for oilfield play a key role. After the second-generation demulsifier for oilfield(F46 demulsifier) independently developed by Shenyang Jiufang Technology Company was put into use in Liaohe Oilfield, Oil demulsifier for the end users not only met the demand for crude oil treatment, but also reduced the dosage of the F46 demulsifier by 8% compared to the first-generation chemical demulsifier.

Our company formulates the development plan of oilfield demulsifie agents based on the properties of oilfield oil products and the production process. When the water cut in the oilfield rises and the performance of the F46 demulsifier for oilfield in use needs to be improved, our company promptly conducts on-site evaluations and process tests and finally optimizes the applicable products(Oil demulsifier) and realizes production and application. The application of oil demulsifiers in the combined devices of the oilfield can achieve good results, effectively remove water droplets in the emulsions, improve the demulsification efficiency, reduce energy consumption and increase the economic benefits of enterprises.

Basic Principles of chemical demulsifier Experimental Design

1. Single-Variable Principle: Only one parameter (such as dosage) is changed in each experiment, while other conditions (temperature, time, etc.) remain consistent. This ensures that the results can be attributed to the specific variable being tested.

2. Parallel-Experiment Principle: Each condition should be repeated at least 3 times to reduce random errors. The average value of the results is taken.

3. Rationality of Gradient Setting: The parameter gradient should cover the possible effective range (for example, the dosage ranges from 0.01% to 1%). Avoid missing the optimal point due to an overly wide or narrow gradient.

4. Consistency of Emulsion: The emulsion used in the experiment should be prepared uniformly. Control factors such as the type and concentration of the emulsifier, stirring speed, and emulsification time to ensure consistent initial stability. This can be verified by measuring the particle size distribution with a laser particle size analyzer.

Industry-specific attributes

| Name | Chemical demulsifier | |||

| Items | Indicator | |||

| Application | Crude Treatment(F46 demulsifier) | |||

Other Attributes

| Appearance | Yellow to Brown liquid,no impurities | |||

| Odor | Slightly Odorless | |||

| Density (20°C ) | 1.1- 1.25 g/ml (9.51-9.85 lb/gal) | |||

| Content(%) | >35 | |||

| Viscosity (20°C ) | < 150cps | |||

| PH (20°C) | 3~6 | |||

| Freezing point | 12°C (10°F) | |||

| Boiling point | 99 °C (210°F) | |||

| Solubility in water | Soluble,easily dispersible | |||

| Closed flash point,℃ | ≥93.3 | |||

| Shelf life | 12 months | |||

Supply Ability

| Supply Ability | 1000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |