Demulsifier For crude Dehydration In Oilfield

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 1000Metric Tons per Month

1.Crude treatment by demulsifier is a type of chemical additive in oilfield.

2. Demulsifier dewatering ,also named demulsifier dehydration , is a additive for oily sludge is used for pretreatment process.

3.Crude treatment by demulsifier is a key link in oilfield.

Download

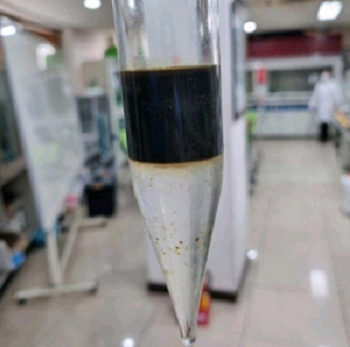

Demulsifier additive for oily sludge is a kind of yellow to brown liquid, without impurities and slightly odorless, which is soluble in water and easily dispersible.

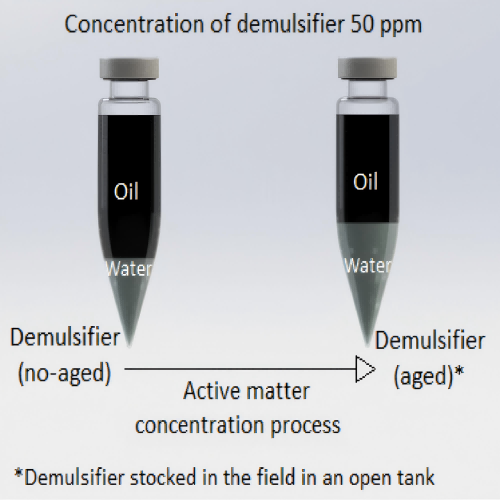

Customized oilfield use demulsifier with different parameters can be produced according to specific requests of the clients and situations. Oilfield use demulsifier dewatering, also named oilfield use demulsifier dehydration in the crude process treatment. Up to 99% the rate of demulsifier dewatering, if you select the suitable demulsifier in jar test.

Our technical engineer can visit your site to provide technical service and then free samples can be delivered to clients. The demulsifier additive for oily sludge product is always packed in drums or IBCs, which is used for oil-water separation and oily sludge treatment in the oilfield.

Crude treatment by demulsifier has stable performance and the shelf life is 12 months.

As a demulsifier dewatering, high carbon alcohol block polyethers owe their advantages to their unique molecular structure design and flexible performance regulation.

Compared with traditional demulsifier additive for oily sludge (such as amines, phenolic resin polyethers, fatty acid esters, etc.), they stand out in terms of adaptability, efficiency, and environmental friendliness.

The specific advantages are as follows:

1. Precisely Adjustable Structure, Excellent Adaptability

The molecules of demulsifier dewatering is composed of a "high carbon hydrophobic chain + EO/PO hydrophilic block".

By adjusting three core parameters:"the length of the high carbon chain (C₈ - C₂₂), the EO/PO ratio, and the block sequence (EO-PO or PO-EO), the hydrophilic lipophilic balance value (HLB) and interfacial activity can be precisely regulated, thus adapting to different types and levels of complexity of emulsions:

For "water-in-oil (W/O)" emulsions (such as crude oil), increasing the PO ratio (enhancing hydrophobicity) can strengthen the affinity with the oil phase.

For "oil-in-water (O/W)" emulsions (such as oily wastewater), increasing the EO ratio (enhancing hydrophilicity) can improve the interaction efficiency with the water phase.

This "custom-made" ability far exceeds that of traditional oilfield use demulsifier with fixed structures, enabling it to handle diverse industrial scenarios (such as the properties of crude oil from different oilfields and oily wastewater from different processes).

2. High Demulsification Efficiency, Fast and Thorough Separation

Strong Interfacial Adsorption Ability: The hydrophobic chain can quickly insert into the hydrophobic region of the emulsion interface film, and the hydrophilic block interacts with the water phase, competitively replacing the original emulsifiers (such as resins and asphaltenes in crude oil) and efficiently disrupting the rigid structure of the interface film.

Remarkable Droplet Coalescence Promotion Effect: The "bridging" effect of the molecular chain can prompt small droplets to collide and merge into large droplets, accelerating the oil-water separation (for example, during crude oil demulsification, the dewatering rate is 10%-30% higher than that of traditional amine - based demulsifiers).

Clear Separation Interface: After demulsification, the water content in the oil phase or the oil content in the water phase is low (for example, the water content of crude oil can be reduced to less than 0.5%, and the oil content of wastewater can be reduced to less than 10mg/L), reducing the subsequent treatment burden.

3. Excellent Anti interference Ability, Adaptable to Complex Working Conditions

As a non ionic demulsifier additive for oily sludge, the performance of crude treatment by demulsifier is less affected by the system environment:

Acid resistant, Alkali resistant, and High salt tolerant: It can still function stably in high salinity oilfield produced fluids (with a salt concentration of over 10⁴mg/L) and acidic/alkaline oily wastewater (pH 3-11). In contrast, traditional anionic crude treatment by demulsifier is easily affected by salt ions, and cationic demulsifier additive for oily sludge tend to fail under acidic conditions.

High temperature resistant: It is not easily decomposed in high temperature environments (such as 50-120℃ in crude oil gathering and transportation), making it suitable for high temperature scenarios such as thermal recovery oilfields.

Good Compatibility with Other Additives: It can co-exist with commonly used additives in oilfields, such as viscosity reducers, bactericides, and corrosion inhibitors, without precipitation or failure, avoiding impacts on process stability due to compatibility issues.

4. Low toxicity and Environment friendly, Reducing Secondary Pollution

Good Biodegradability: The ether bonds and hydroxyl groups in the molecule are easily decomposed by microorganisms (especially when the carbon chain length is moderate and the EO ratio is reasonable, the biodegradation rate can reach over 80%), which is far better than the hardly degradable phenolic resin based demulsifier additive for oily sludge.

Low Irritation and Low Toxicity: It poses little harm to operators and the ecological environment (such as soil and water bodies), meeting the requirements of environmental protection regulations for "green chemicals", especially in fields with strict environmental protection standards (such as municipal oily wastewater treatment and offshore oilfield development).

5. Extremely Wide Application Range, Strong Scenario Compatibility

It can handle both core industrial scenarios (such as crude treatment by demulsifier dehydration and refinery wastewater treatment) and fine scale fields (such as demulsification after emulsion polymerization and waste oil recovery in food processing), and there is no need to significantly adjust the process for different scenarios, reducing the application threshold.

In conclusion, high carbon alcohol block polyethers, with their comprehensive advantages of "strong adjustability, high efficiency, anti interference, and environmental friendliness", have become the preferred crude treatment by demulsifier in the field of industrial emulsion separation. Their advantages are even more prominent in complex working conditions and scenarios with strict environmental protection requirements.

Industry-specific attributes

| Name | Demulsifier additive for oily sludge | |||

| Items | Indicator | |||

| Application | Demulsifier dewatering | |||

Other Attributes

| Appearance | Yellow to Brown liquid,no impurities | |||

| Odor | Slightly Odorless | |||

| Density (20°C ) | 1.1- 1.25 g/ml (9.51-9.85 lb/gal) | |||

| Content(%) | >35 | |||

| Viscosity (20°C ) | < 150cp | |||

| PH (20°C) | 3~6 | |||

| Freezing point | 12°C (10°F) | |||

| Boiling point | 99 °C (210°F) | |||

| Solubility in water | Soluble,easily dispersible | |||

| Closed flash point,℃ | ≥93.3 | |||

| Shelf life | 12 months | |||

Supply Ability

| Supply Ability | 1000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |