Crude Separation In Demulsifier

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 1000Metric Tons per Month

1. Demulsifier for separation are screened according to different oil qualities (such as waxy oil, bituminous oil or light oil) and treatment

temperatures.

2. Oil water separation lie in separating water from oil.

3. Demulsifier for crude oil need to take jar test.

Download

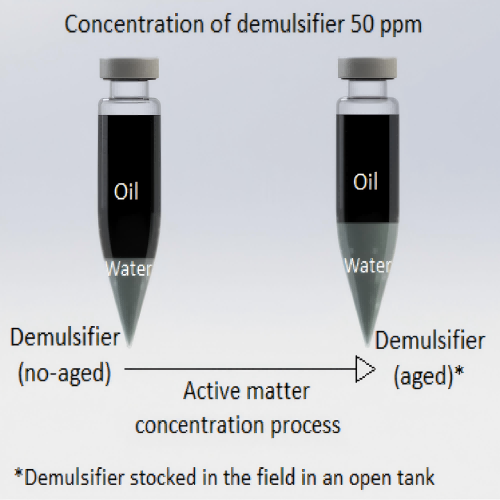

Phenolic amine resin block polyether oil water demulsifier is a type of high efficiency separating agents designed for emulsions, especially the oil water emulsions formed during crude oil extraction and processing. Their efficacy mainly stems from the synergistic effect between the lipophilic skeleton of the phenolic amine resin and the hydrophilic segments of the block polyether (such as polyoxyethylene EO and polyoxypropylene PO) in their molecular structure.

The specific effects are as follows:

1.High efficiency Demulsification and Oil Water Separation

As the core function, their molecules can quickly adsorb at the oil water interface, replacing or disrupting the stable interface film formed by natural emulsifiers in the emulsion. This reduces the interfacial tension, promotes the coalescence and sedimentation of the dispersed phase (water droplets or oil droplets), and ultimately achieves fast acting breaker separation. It is particularly effective for the W/O (water - in - oil) emulsions commonly found in crude oil extraction.

2. Wide Applicability of oil water separation

By adjusting the ratio and chain length of EO/PO in the block polyether, the lipophilic - hydrophilic balance (HLB value) of the molecule can be flexibly regulated, enabling it to adapt to different types of crude oil systems: It is suitable for heavy crude oils with high viscosity and high gum/asphaltene content.

It can handle crude oil emulsions with a high water content (water content of 30%-90%) or high salinity (mineralization degree of 10⁴-10⁵ mg/L).

It has a good effect on both the emulsions containing seawater in offshore oilfields and those containing formation water in onshore oilfields.

3. Fast acting Dewatering and High Dewatering Rate

It can significantly accelerate the coalescence and sedimentation speed of water droplets, shortening the demulsification time (usually reducing the traditional demulsification time by 30%-50%). Moreover, it has a high dewatering rate (generally up to over 90% in oil water separation). The oil content in the separated sewage is low, which can reduce the subsequent sewage treatment load. At the same time, it reduces the water content of crude oil, decreasing the energy consumption (such as heating energy consumption) during transportation and processing.

4. Good Low temperature Demulsification Performance when using demulsifier for separation

Traditional demulsifier for crude oil often require high temperatures (60-80℃) for assistance. However, due to the flexibility of the molecular segments and interfacial activity of phenolic amine resin block polyether, it can still effectively demulsify at lower temperatures (30-50℃), reducing heating energy consumption. This is especially suitable for crude oil systems that are sensitive to temperature.

5. Strong Anti interference Ability

It has good tolerance to impurities (such as sediment, wax, additive residues), acid base environments (pH 5-9), or electrolytes (salts) that may exist in crude oil. It is not easily rendered ineffective by external interference, ensuring stable performance under complex working conditions.

Through 20 years focus on customized chemical products and technical service,we also got to know many outstanding clients online.

Industry-specific attributes

| Name | Demulsifier for crude oil | |||

| Items | Indicator | |||

| Application | Demulsifier for oil in water | |||

Other Attributes

| Appearance | Yellow to Brown liquid,no impurities | |||

| Odor | Slightly Odorless | |||

| Density (20°C ) | 1.1- 1.25 g/ml (9.51-9.85 lb/gal) | |||

| Content | 35% | |||

| Viscosity (20°C ) | < 150cp | |||

| PH (20°C) | 3~6 | |||

| Freezing point | 12°C (10°F) | |||

| Boiling point | 99 °C (210°F) | |||

| Solubility in water | Soluble,easily dispersible | |||

| Closed flash point,℃ | ≥93.3 | |||

| Shelf life | 6 months | |||

Supply Ability

| Supply Ability | 1000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |