Demulsifier In Industrial Oilfield

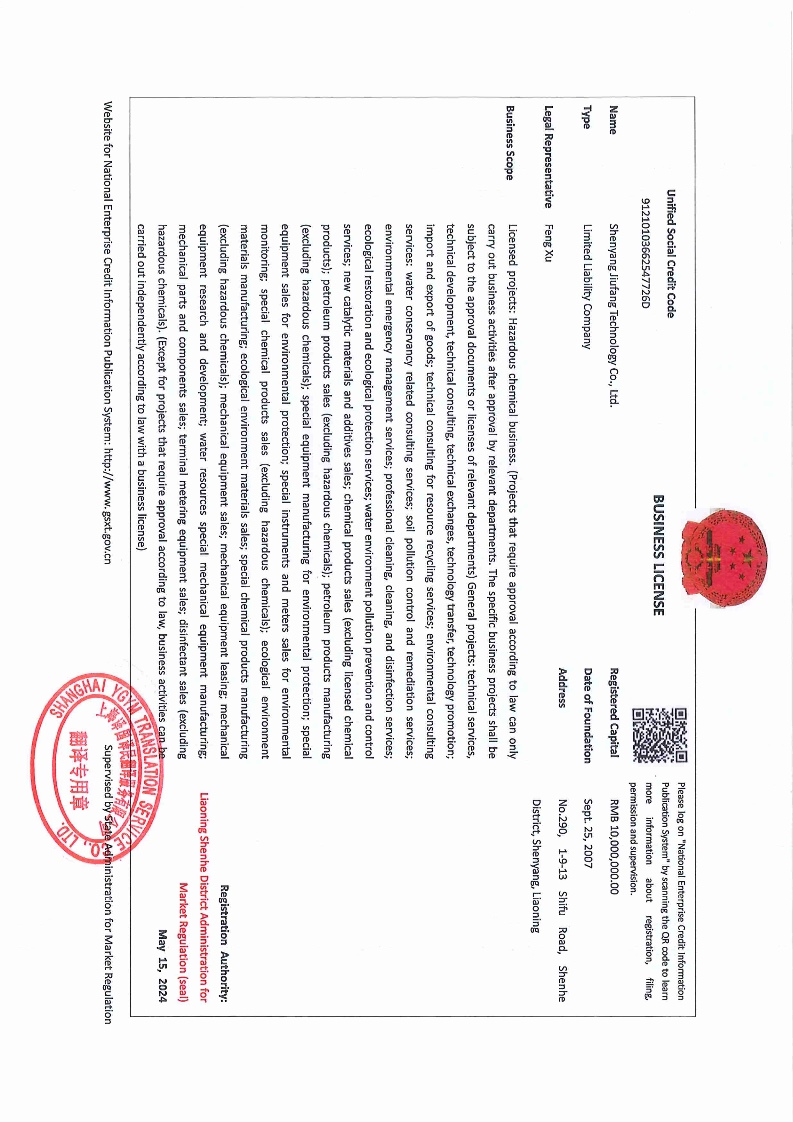

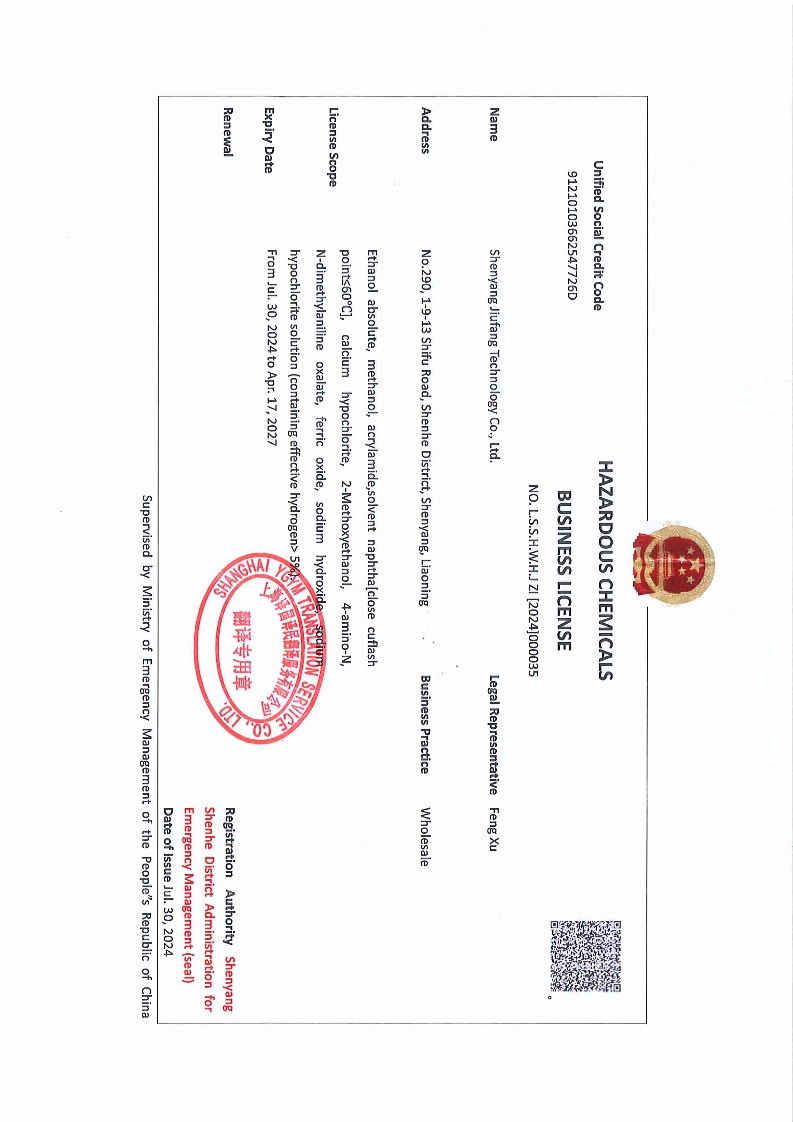

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 1000Metric Tons per Month

1.As a demulsifier of supplier and manufacturer, Our factory could produce 1000tons demulsifier product per month.

2.Depends on business format of demulsifier wholesale, our company have cooperated with more than 300 oilfield&plants all over the world.

Download

The demulsification effect of the demulsifier product (isocyanate modified phenolic resin based polyether) is closely related to temperature.

The core reason is that temperature can affect the molecular movement activity, the stability of the emulsion interface film, and the structural stability of the demulsifier product.

Considering the chemical structure of demulsifier product (the rigid skeleton of phenolic resin, the cross linking/polar groups introduced by isocyanate, and the hydrophilic lipophilic balance of the polyether segment), the demulsification effects at different temperatures can be analyzed in the following intervals:

1. Low temperature range (<40℃): The demulsification efficiency is relatively low and the speed is slow. At low temperatures, molecular thermal motion is weak. The rate at which demulsifier product molecules diffuse to the oil-water interface decreases, and the flexibility of the polyether segments is restricted by the low temperature environment, making it difficult to fully expand. As a result, the competitive of demulsifier product adsorption ability with natural emulsifiers in crude oil (such as asphaltenes and resins) decreases. At the same time, the viscosity of the crude oil emulsion is high at low temperatures, and the sedimentation resistance of water droplets after coalescence is large, further delaying the dewatering process.

Effect manifestation: The demulsification speed is slow (the dewatering time may be extended by more than 50%), the dewatering rate is relatively low (usually <70%), and the water content in the oil phase is relatively high. However, due to the certain polar effects that the carbamate groups and phenolic hydroxyl groups introduced by isocyanate modification can still maintain at low temperatures, it still has some demulsification activity for light crude oil or low viscosity emulsions (such as with a water content <30%), but the efficiency is lower than that at medium and high temperatures.

2.Medium temperature range (40-100℃): The demulsification efficiency is the highest, and the comprehensive performance is optimal. This temperature range is the "golden range" for this type of demulsifier product for the following reasons:

Enhanced molecular activity: As the temperature rises, the movement of demulsifier product molecules speeds up, and the flexibility of the polyether segments (especially the hydrophobic segments) increases. They can quickly diffuse to the oil water interface. Through polar groups (phenolic hydroxyl groups, carbamate groups), they can form hydrogen bonds or Van der Waals forces with the polar components in the interface film (such as the carboxyl and hydroxyl groups of resins), efficiently replacing natural emulsifiers and disrupting the stability of the interface film. Reduced emulsion viscosity: At medium temperatures, the viscosity of the crude oil emulsion significantly decreases (especially for heavy crude oil), the sedimentation resistance of water droplets after coalescence decreases, and the dewatering speed accelerates (usually, the main dewatering can be completed within 30-60 minutes).

Appropriate structural stability: The phenolic resin skeleton itself has excellent heat resistance (the decomposition temperature is usually >200℃), and the carbamate bonds introduced by isocyanate are stable below 100℃, with no obvious hydrolysis or decomposition, ensuring that the activity of the demulsifier does not decay.

Effect manifestation: The dewatering rate can reach over 90%, the water content in the oil phase can be reduced to less than 0.5%, and the clarity of the water phase is high (with few suspended solids). It is particularly effective for heavy crude oil emulsions with high gum and asphaltene content (water content 30%-70%), and both the demulsification speed and the thoroughness of dewatering are better than those of ordinary polyether demulsifier product.

3. High temperature range (100-150℃): The demulsification efficiency is stable, but thermal stability needs to be noted. In the range of 100-150℃, the demulsifier product can still maintain a high activity: Molecular motion further intensifies, the interface film is disrupted more rapidly, and the viscosity of the crude oil emulsion is extremely low, so the sedimentation speed of water droplets is extremely fast. The initial dewatering efficiency is even higher than that at medium temperatures (for example, at 120℃, the dewatering rate can reach 95% in 30 minutes). The phenolic resin skeleton and polyether segments have excellent stability at this temperature. However, it should be noted that the carbamate bonds introduced by isocyanate may undergo slight hydrolysis under long term high temperatures (>130℃, lasting for several hours), resulting in a decrease in polar groups and a slight decline in the activity of the demulsifier product (the dewatering rate may decrease by 3%-5%).

Applicable for demulsifier product: It is suitable for high temperature produced fluids in deep wells (such as reservoir temperatures of 120-140℃) or processes that require high temperature and fast acting emulsion breaker (such as pretreatment before electro dehydration).

However, the duration of high temperature exposure should be controlled (usually recommended to be ≤4 hours) to avoid a decline in activity.

4. Extremely high temperature (>150℃): The demulsification efficiency drops significantly, and demulsifier for industrial use is not recommended. When the temperature exceeds 150℃, the hydrolysis of the carbamate bonds introduced by isocyanate modification intensifies, and even partial degradation of the phenolic resin skeleton may occur, leading to the destruction of the demulsifier product molecular structure:

A large number of polar groups decrease, and the binding ability to the interface film significantly declines. The polyether segments may break due to high temperature oxidation, disrupting the hydrophilic lipophilic balance and making it difficult to adsorb effectively at the oil water interface.

Effect manifestation: The dewatering rate drops sharply to below 70%, the oil phase entrains a large amount of water, and the water phase becomes turbid (the oil content increases), losing its practical application value.

The optimal demulsification temperature for isocyanate modified phenolic resin based polyether is 40-100℃, at which the demulsification efficiency is high, the speed is fast, and the dewatering is thorough. It can still be used stably in the range of 100-150℃, but the duration of high temperature exposure needs to be controlled. The efficiency is relatively low below 40℃, and the effect drops significantly above 150℃ due to structural damage. In practical applications, combined with the type of crude oil (light/heavy), the water content of the emulsion, and the extraction temperature, the process temperature should be controlled within 40-150℃ (preferably 60-120℃) to give full play to its best performance.

Industry-specific attributes

| Name | Industrial demulsifier | |||

| Items | Indicator | |||

| Application | Demulsifier for industrial use | |||

Other Attributes

| Appearance | Yellow to Brown liquid,no impurities | |||

| Odor | Slightly Odorless | |||

| Density (20°C ) | 1.1- 1.25 g/ml (9.51-9.85 lb/gal) | |||

| Content | >35% | |||

| Viscosity (20°C ) | < 150cp | |||

| PH (20°C) | 3~6 | |||

| Freezing point | 12°C (10°F) | |||

| Boiling point | 99 °C (210°F) | |||

| Solubility in water | Soluble,easily dispersible | |||

| Closed flash point,℃ | ≥93.3 | |||

| Shelf life | 12 months | |||

Supply Ability

| Supply Ability | 1000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |