Fast Acting Demulsifier

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 1000Metric Tons per Month

1. Demulsifier oil and gas is a product formed by the block polyether of ethylene oxide and propylene oxide.

2. Fast acting emulsion breaker depends on temperature of separation treatment.

3. Demulsifier separation crude oil are divided into oil-based products and water-based products.

Download

Fast acting emulsion breaker is a kind of yellow to brown liquid,no impurities with slightly odorless,which is soluble in water and easily dispersible.

Demulsifier fast acting with different parameters could be produced according to the specific request&situation of demulsifier oil and gas.

Our technical engineer could visit your spot to supply technical service,then free sample could be delivered to you.

Demulsifier and reverse demulsifier product are always be packed by drum or IBC,which is used for oil-water separating&oily sludge treatment in oilfield,it has stable performance and shelf time is 12Months.

In oilfield development, the crude oil is prone to forming stable emulsions due to the presence of natural emulsifiers (such as asphaltenes, resins, clay particles) or artificially injected surfactants (such as oil displacement agents).

The fast acting emulsion breaker demulsifier is the core chemical for treating the produced fluid. Its application runs through the entire process of the crude oil from the wellhead to separation and treatment. The core objective is to quickly break the stability of the emulsion, achieve efficient oil water separation, and meet the requirements of crude oil transportation, sewage reinjection, or discharge.

The following are the specific application details:

1. Application Scenarios and Process Stages

The treatment of the crude oil needs to go through processes such as "preliminary separation → deep dewatering → sewage purification". The fast acting emulsion breaker demulsifier plays a crucial role in each stage:

1). Pretreatment at the Wellhead and Gathering Pipelines

After the crude oil is extracted from the wellhead, the temperature and pressure drop suddenly, which may enhance the stability of the emulsion. If not treated in a timely manner, it will increase the difficulty of subsequent separation. In this stage, by injecting the fast acting emulsion breaker demulsifier through the wellhead chemical adding device,

it can: Inhibit further emulsification of the emulsion (preventing the intensification of emulsification due to pipeline turbulence);

Initially break the oil water interface film, reducing the burden on subsequent separation, especially suitable for the produced fluid from high production wells or high viscosity crude oil (such as heavy oil).

2). Dewatering Process at Gathering Stations/Combined Stations

This is the core stage of crude oil treatment. The fast acting emulsion breaker demulsifier cooperates with physical processes (sedimentation, electrochemistry, flotation, etc.) to achieve deep dewatering:

Gravity Settling Tanks: The demulsifier fast acting agent promotes the coalescence of small water droplets into large droplets, accelerating sedimentation (the sedimentation time originally taking several hours can be shortened to 1-2 hours);

Electrochemical Dehydrators: Under the action of an electric field, the demulsifier separation crude oil reduces the interfacial tension between oil and water, promoting the directional migration and coalescence of water droplets, and greatly improving the dewatering efficiency (for example, reducing the water content of crude oil from 20% to less than 0.5%, and shortening the treatment time by more than 30%);

Three Phase Separators: For the crude oil containing gas, the demulsifier, together with the flotation effect, realizes the simultaneous separation of oil, gas, and water, reducing the retention of the emulsion layer.

3). Treatment of crude oil in the High water cut Period

After the oilfield development enters the medium to high water cut period (water content > 60%), the crude oil is mostly an oil - in - water (O/W) emulsion with stronger stability. The demulsifier fast acting agent (anionic or non - ionic types need to be selected specifically) can quickly adsorb onto the surface of oil droplets, destroy the double electric layer, promote the coalescence and floating of oil droplets, and reduce the oil content in the sewage (from several hundred mg/L to less than 10 mg/L, meeting the reinjection standard).

2. Core Action Mechanisms In crude oil, the fast acting breaker demulsifier achieves efficient separation through the following methods:

1). Interface Film Destruction: Demulsifier fast acting agent molecules (such as polyethers, amine derivatives) preferentially adsorb at the oil - water interface, replacing natural emulsifiers (asphaltenes, resins), weakening the strength of the interface film, and causing it to rupture;

2). Water Drop Coalescence: Through the bridging effect, dispersed small water droplets (diameter < 10μm) are coalesced into large droplets (diameter > 50μm), enhancing the gravity - sedimentation ability;

3). Synergistic Viscosity Reduction: Some demulsifier fast acting agent can reduce the viscosity of crude oil (especially for heavy oil produced fluid), reducing the sedimentation resistance of water droplets and further accelerating the separation.

3. Key Influencing Factors and Optimization Strategies

The properties of the crude oil are complex (with large differences in water content, viscosity, sand content, and degree of emulsification), and the application of the demulsifier separation crude oil needs to be optimized accordingly:

1). Adaptation to Produced Fluid Characteristics

For crude oil with a low water content (water content < 30%, W/O type): Oil soluble demulsifier fast acting agents (such as polyoxypropylene ether) are preferentially selected to enhance their dispersibility in crude oil;

For crude oil with a high water content (water content > 60%, O/W type): Water soluble demulsifier fast acting agents (such as sulfonates) are selected to improve their diffusion efficiency in water;

For crude oil containing sand/polymer (such as in polymer flooding oilfields): A flocculant (such as polyaluminium chloride) needs to be compounded to prevent solid particles from hindering oil - water separation.

2). Synergy of Process Parameters

Temperature: Moderate heating (40 - 80°C) can enhance the activity of the demulsifier separation crude oil which is particularly important for heavy oil produced fluid;

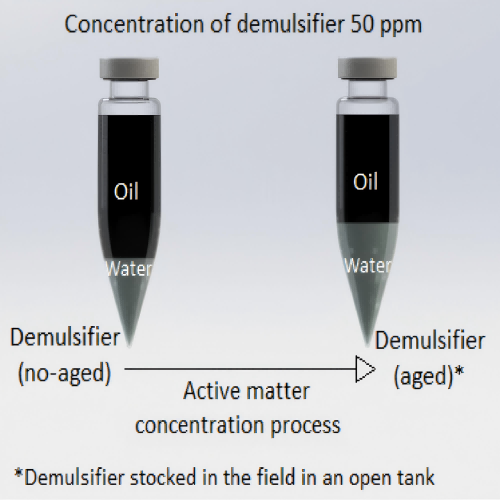

Dosage: Usually, it is 50-500 ppm of the mass of the produced fluid. Excessive dosage may lead to "re-emulsification" (re - forming a stable emulsion), and the optimal dosage needs to be determined through on - site small - scale tests;

Residence Time: The demulsifier fast acting can shorten the residence time in a traditional settling tank from 6-8 hours to 2-3 hours, which is suitable for the requirements of continuous production.

4. Application Value and Benefits

Improve Production Efficiency: Shorten the separation cycle and increase the treatment capacity of the crude oil;

Reduce Energy Consumption and Costs: Reduce the energy consumption of processes such as heating and stirring, and at the same time, reduce the transportation cost of crude oil transportation;

Ensure the Stability of Subsequent Processes: Dehydrated crude oil can directly enter the refining process, and up - to - standard sewage reinjected into the formation can reduce water resource consumption and avoid environmental pollution.

In summary, the fast acting emulsion breaker demulsifier is the core technical means for "oil - water separation" of the crude oil. Its application needs to consider the type of oilfield (light oil/heavy oil, conventional/chemical - flooding), the properties of the crude oil, and the treatment process. Through precise selection and parameter optimization, the goal of efficient and low - cost separation can be achieved.

Industry-specific attributes

| Name | Demulsifier fast acting | |||

| Items | Indicator | |||

| Application | Demulsifier separation crude oil | |||

Other Attributes

| Appearance | Yellow to Brown liquid,no impurities | |||

| Odor | Slightly Odorless | |||

| Density (20°C ) | 1.1- 1.25 g/ml (9.51-9.85 lb/gal) | |||

| Content | 35% | |||

| Viscosity (20°C ) | < 150cp | |||

| PH (20°C) | 3~6 | |||

| Freezing point | 12°C (10°F) | |||

| Boiling point | 99 °C (210°F) | |||

| Solubility in water | Soluble,easily dispersible | |||

| Closed flash point,℃ | ≥70 | |||

| Shelf life | 12 months | |||

Supply Ability

| Supply Ability | 1000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |