Oilfield Chemical Demulsifier Product

Brand Jiufang

Product origin Shenyang

Delivery time Lead time: 7days

Supply capacity 1000Metric Tons per Month

1.Our factory could produce 1000tons demulsifier per month.

2.Our company have cooperated with more than 300 oilfield&plants all over the world.

3.Our team own dozens of outstanding engineers and customized products could be supplied.

Download

Demulsifier chemicals is a type of yellow to brown liquid, with no impurities and slightly odorless.

The oilfield demulsifier is soluble in water and easily dispersible. Customized demulsifier product with different parameters can be produced according to the specific requests & situations of the oilfield demulsifier additive compositions.

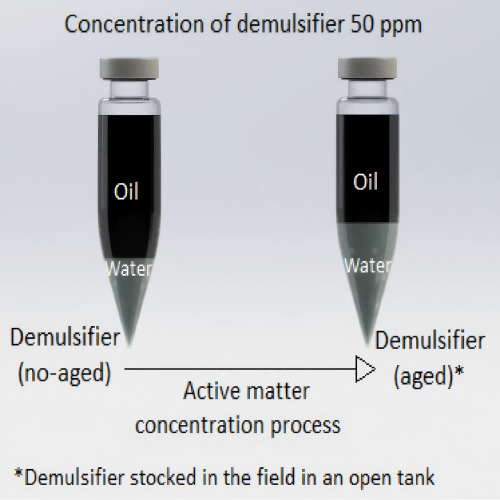

Our technical engineer can visit your site to provide technical service and related demulsifier product and then free samples can be delivered to the clients. The demulsifier product is always packed in drums or IBCs, which is used for oil-water separation & oily sludge treatment in the oilfield. The demulsifier product has stable performance and the shelf time is 12 months.

Core Evaluation of Demulsification Effect--Phenolic resin block polyether(Demulsifier product)

(1) High Dewatering Rate and Strong Adaptability--Demulsifier product

For the produced fluids of heavy crude oil with a high content of gum and asphaltene, the hydrophobic segment of phenolic resin has better compatibility with heavy components. It can more thoroughly peel off the interfacial film, and the dewatering rate can usually reach over 90%. Even in produced fluids with a high water content (such as a water content of over 70%), it can still effectively promote the separation of oil and water.

(2) Fast Dewatering Speed and High Efficiency--Demulsifier chemicals

The block - polyether chain structure (such as the length and proportion of EO/PO) can optimize the molecular diffusion ability, enabling it to quickly reach the oil - water interface and take effect, shortening the demulsification time (usually, the main dewatering process is completed within 30 minutes to several hours), which is suitable for the requirements of industrial continuous treatment. (3) Clear Oil-Water Interface and Little Emulsion Layer--Oilfield demulsifier

After demulsification, there is no obvious emulsion layer residue at the oil water interface. This is because the phenolic - resin block - polyether can effectively remove emulsifiers (such as gum and asphaltene) on the interfacial film, avoiding secondary emulsification and facilitating the subsequent separation and recovery of the oil phase and the water phase.

(4) Low Oil Content in the Dewatered Sewage--Demulsifier additive compositions

Since it can promote the coalescence of tiny water droplets into large droplets and their sedimentation, the content of dispersed oil and emulsified oil in the dewatered sewage is significantly reduced (usually can be reduced to less than 50 mg/L), reducing the pressure of subsequent sewage treatment.

Through 20 years focus on customized demulsifier chemicals and technical service,we also got to know many outstanding clients online.

Demulsifier additive compositions

Industry-specific attributes

| Name | Oilfield demulsifier chemicals | |||

| Items | Indicator | |||

| Application | Demulsifier for oil Treatment | |||

Other Attributes

| Appearance | Yellow to Brown liquid,no impurities | |||

| Odor | Slightly Odorless | |||

| Density (20°C ) | 1.1- 1.25 g/ml (9.51-9.85 lb/gal) | |||

| Content(%) | >35 | |||

| Viscosity (20°C ) | < 150cps | |||

| PH (20°C) | 3~6 | |||

| Freezing point | 12°C (10°F) | |||

| Boiling point | 99 °C (210°F) | |||

| Solubility in water | Soluble,easily dispersible | |||

| Closed flash point,℃ | ≥93.3 | |||

| Shelf life | 12 months | |||

Supply Ability

| Supply Ability | 1000Metric Tons per Month | |||

Lead Time

| Quantity(kilograms) | 1~50 | >50 | |

| Lead Time(days) | 7 | negotiated | |